- Joined

- Apr 30, 2015

- Messages

- 11,349

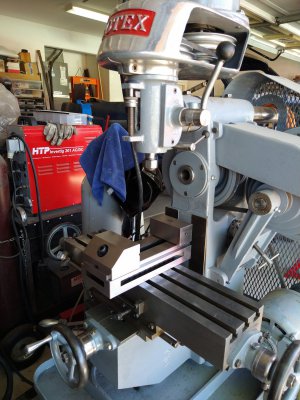

Nope, no real problems. Having 3 tee slots is nice but I mostly use the middle one. I use the swivel base a lot, especially when using the horizontal spindle to hold an endmill or flycutter

I wish I knew who made that vise though. No markings on it at all except degrees

I wish I knew who made that vise though. No markings on it at all except degrees