- Joined

- Sep 8, 2019

- Messages

- 4,392

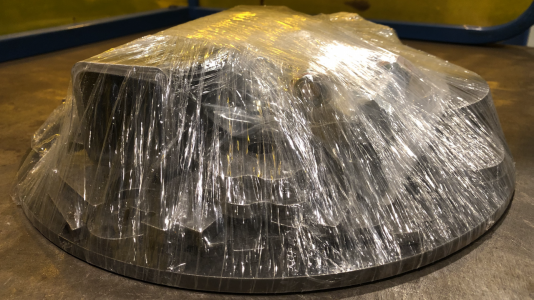

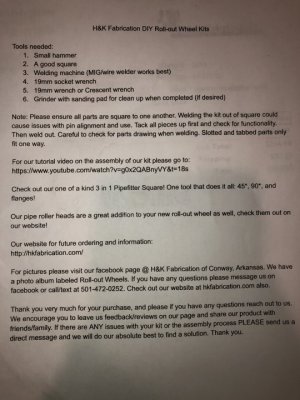

Today, I received a rollout wheel kit today from HK Fabrication in Conway, AR.

I will post pictures of what I received.

I get to weld this up myself. I also get to assemble a trailer spindle to a trailer hub. See pictures of these trailer parts that I bought from Tractor Supply.

The used plain back 8” 3J scroll chuck that I bought should bolt right on, but the chuck does not include a lathe chuck key or mounting bolts.

If I make my own lathe chuck key (which I prefer), is mild steel good enough? I won’t be tightening the chuck too much, as the chuck is only holding the pipe (or tubing) for welding, & never for machining. Maybe I could make the body of the chuck key out of 4140 prehard.

I will get to choose which welding process to use for welding this rollout wheel kit. The last project I did was all SMAW, so I won’t choose that.

I just got a new tank of acetylene that I haven’t tried yet. I always love to gas weld, but I have been doing a lot of gas welding lately. As such, I should choose GTAW or GMAW because it has been awhile since I have used either one of those processes.

I will choose GTAW (never my favorite process for carbon steel) because I think my wireless foot pedal is out of batteries.

I will post pictures of what I received.

I get to weld this up myself. I also get to assemble a trailer spindle to a trailer hub. See pictures of these trailer parts that I bought from Tractor Supply.

The used plain back 8” 3J scroll chuck that I bought should bolt right on, but the chuck does not include a lathe chuck key or mounting bolts.

If I make my own lathe chuck key (which I prefer), is mild steel good enough? I won’t be tightening the chuck too much, as the chuck is only holding the pipe (or tubing) for welding, & never for machining. Maybe I could make the body of the chuck key out of 4140 prehard.

I will get to choose which welding process to use for welding this rollout wheel kit. The last project I did was all SMAW, so I won’t choose that.

I just got a new tank of acetylene that I haven’t tried yet. I always love to gas weld, but I have been doing a lot of gas welding lately. As such, I should choose GTAW or GMAW because it has been awhile since I have used either one of those processes.

I will choose GTAW (never my favorite process for carbon steel) because I think my wireless foot pedal is out of batteries.

Last edited: