- Joined

- Jan 2, 2014

- Messages

- 8,852

I get it that everyone's first impression of me and what I am doing is I'm a hack. I tried to go into this thing with all the info I needed, I asked a few people that had done similiar on other gearhead lathes, I asked the distributor for the machine and I asked here.

Hey Rich,

Don't let the critical yet useless reply of one crank get you down.

What I see from here is that you're trying your best to deal with a crappy situation.

I think we've all been there.

Take it slow and methodical.

Walk away when the frustration level gets high........personally I find this difficult to do, but have learned that, for me, I must do it.

(venting prevents ex..plo..si..on)

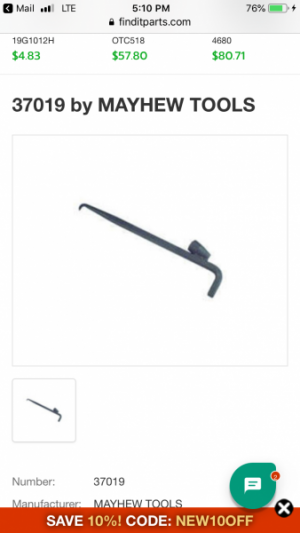

Got any pictures of the clip you need to remove, or shots from the manual?

That may help drive some ideas too.

One thing I have seen in the past is drilling holes in the sides of the jaws of a set of pliers to put pins in as custom snap ring pliers.

Maybe you can find a cheap pair of long nose pliers that you could sacrifice for that.

Good Luck!

-brino