Thanks Phil that's what I was planning on doing.

I am however worried about parting stuff off I don't understand the difference between the parting blades and holders. It seems like higher quality may be better here or a specific style with this smaller machine.

And was mostly asking, if you were to be in the market for a set of insert tool holders considering the price of inserts and interchangabality between turning and boring what would you suggest.

Again thanks to all for the quick replys

Danny

Danny,

Since you asked about parting tools here is a few photos that I lifted from Ebay. I'm sure that some of the real experts can chime in and give you some advise.

I bought a QCTP set that came with a parting blade holder.

For the life of me, I always had problems with this style holder actually holding onto the parting blade. I don't know if it's the style of holder that is the issue or if it's just a messed up example of a copy of one of the major manufacturers. For a while I went back to using the old style lantern type holder. This style is what I learned on, and is what was used on manual machines for decades in thousands of shops.

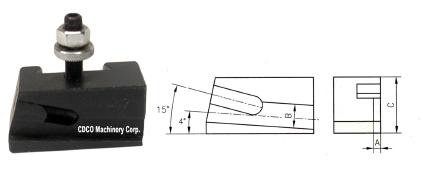

Then I came across a NOS parting tool block that takes parting blades w/carbide inserts. This isn't a great example of the tool block but it's the best one that shows the profile. The only reason I use this is new one instead of the old style is the ease in just dropping it into the QCTP and not having to swap the QCTP with the lantern post.

here is a shot of the "self grip" insert holder

I hope this helps.

Mike

). My 1944 vintage Monarch is a monster of a machine but has a top speed of only 700. Rarely do I run it over 425 and carbide inserts do well.

). My 1944 vintage Monarch is a monster of a machine but has a top speed of only 700. Rarely do I run it over 425 and carbide inserts do well.