Regarding the issue of being/not being able to cut "prime" thread pitches ...

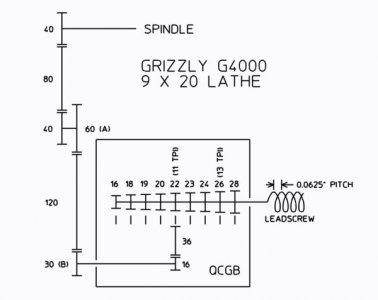

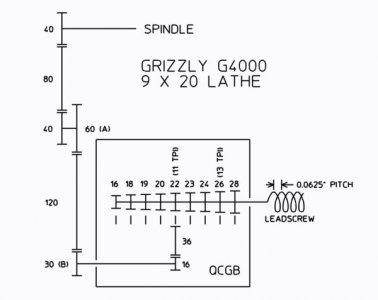

As I mentioned previously, my Grizzly G4000 (9x20) lathe claims to be able to cut both 11 pitch and 13 pitch threads. Just for fun, I took the QCGB apart and counted gear teeth (OK, coulda looked in the manual. I did afterward, just to verify my counts.) The following diagram shows all the gears involved in creating the two thread pitches in question. The "A" and "B" gears are replaceable; 60T and 30T are ones specified on the threading chart, as are the 22T and 26T QCGB gears, for 11 and 13 pitch, respectively.

Let's do the math:

Thread pitch (when set for 11 TPI) = 1 spindle turn X 40/40 X 60/30 X 16/22 X .0625"

= 0.09090909(repeating)"

= 1/11" per turn EXACTLY

Thread pitch (when set for 13 TPI) = 1 spindle turn X 40/40 X 60/30 X 16/26 X .0625"

= 0.076923(etc.)"

= 1/13" per turn EXACTLY

So, as far as I can tell, the claim that you can't get "prime" tread pitches with a QCGB is DISPROVEN. Mikey, I have not read the author (Cleeve) that you cited, so I don't know how he arrived at his claim**. But given the gearing involved, there's on way (other than maybe inaccuracy in the leadscrew) that you can arrive at anything other than the results I've calculated above. It's in the hardware!

**PS - I'm wondering if Cleeve might have been referring to

producing gears with prime tooth counts(?) Despite having a goodly number of rows of holes on the dividing plates, my own rotary table is incapable of producing any prime number gears from 67 on up. It

can produce prime interval numbers (gears or whatever) with values between 2 and 61, because the index plates include all these numbers or multiples thereof. And yes, you can produce pseudo-prime gears by cheating a little bit. For instance, I figured out that if absolutely necessary, I could probably produce an acceptable 127 tooth gear. (use the 62 hole plate, advance 44 holes for 15 teeth, then 43 holes for the 16th tooth. Rinse and repeat until done. Maximum error 0.065º)