-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

QCGB question

- Thread starter markba633csi

- Start date

Was this pun itended...........?Interesting thread for me...

- Joined

- Jul 2, 2014

- Messages

- 7,594

I totally missed it...Was this pun itended...........?

B

British Steel

Forum Guest

Register Today

hman said:**PS - I'm wondering if Cleeve might have been referring to producing gears with prime tooth counts(?) Despite having a goodly number of rows of holes on the dividing plates, my own rotary table is incapable of producing any prime number gears from 67 on up. It can produce prime interval numbers (gears or whatever) with values between 2 and 61, because the index plates include all these numbers or multiples thereof. And yes, you can produce pseudo-prime gears by cheating a little bit. For instance, I figured out that if absolutely necessary, I could probably produce an acceptable 127 tooth gear. (use the 62 hole plate, advance 44 holes for 15 teeth, then 43 holes for the 16th tooth. Rinse and repeat until done. Maximum error 0.065º)

Easier and more accurate, make a temporary 127 hole plate (cad or excel piechart), glue to an unwanted AOL CD-ROM and step around worm-ratio hole spaces (or line spaces) to make a first attempt, use that to make another, rinse and repeat, each iteration will be more accurate by the worm ratio so assume a 2* initial error and 90:1 the first try will be out by 2/90*, second 2/8100*, 3rd by 2/729000* - how the first generation were made, way back!

Dave H. (the other one)

- Joined

- May 4, 2015

- Messages

- 3,583

Ok ok buzzes splat brains fizzeled. To much to think get me my machinist handbook.

- Joined

- Feb 17, 2013

- Messages

- 4,406

They had AOL in those days????Easier and more accurate, make a temporary 127 hole plate (cad or excel piechart), glue to an unwanted AOL CD-ROM and step around worm-ratio hole spaces (or line spaces) to make a first attempt, use that to make another, rinse and repeat, each iteration will be more accurate by the worm ratio so assume a 2* initial error and 90:1 the first try will be out by 2/90*, second 2/8100*, 3rd by 2/729000* - how the first generation were made, way back!

Dave H. (the other one)

- Joined

- Feb 17, 2013

- Messages

- 4,406

I've proved out my theories. Prepared two chunks of ¾" PVC pipe, with a bold red lengthwise stripe to make it easy to see the threads.

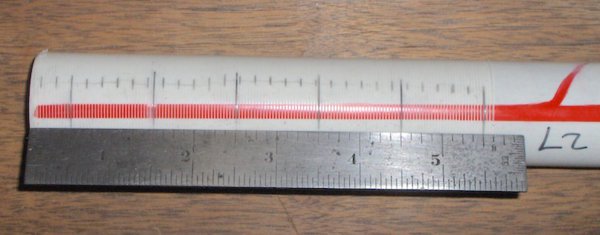

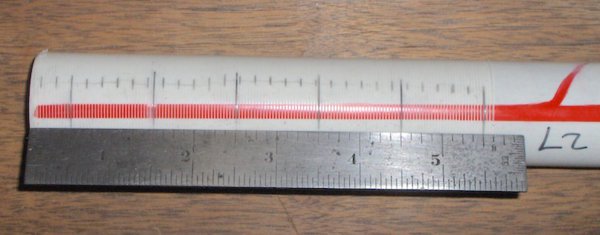

(1) Set up the lathe for 27 TPI per my earlier post, with 30 and 45 tooth gears in the head and selecting the 18 tooth QCGB gear. Took a shallow cut with a new, sharp threading insert. Counted grooves along the red stripe and marked every 27th. Held a ruler against it, and the 27th marks lined up nicely with the half inch marks on the scale.

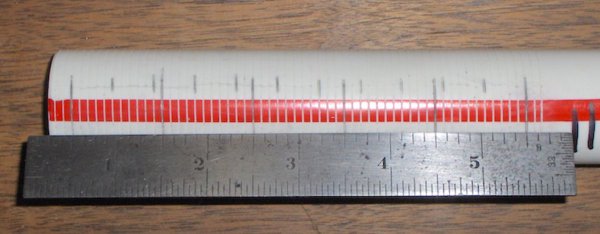

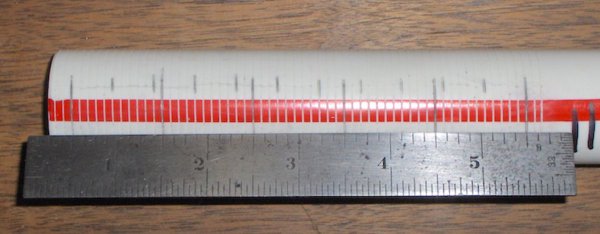

(2) Set up for 11 TPI, according to the threading chart. Took a shallow cut on another piece of PVC, counted grooves, marked every 11th. Results below.

Mikey, I have no idea why you got different results. Possibly because your sharpie moved during the test? But in any case, I think it would be a very good idea for you to go back to your source (Cleve), find the original quote, and post it for us. There may well be some detail that's been overlooked.

(1) Set up the lathe for 27 TPI per my earlier post, with 30 and 45 tooth gears in the head and selecting the 18 tooth QCGB gear. Took a shallow cut with a new, sharp threading insert. Counted grooves along the red stripe and marked every 27th. Held a ruler against it, and the 27th marks lined up nicely with the half inch marks on the scale.

(2) Set up for 11 TPI, according to the threading chart. Took a shallow cut on another piece of PVC, counted grooves, marked every 11th. Results below.

Mikey, I have no idea why you got different results. Possibly because your sharpie moved during the test? But in any case, I think it would be a very good idea for you to go back to your source (Cleve), find the original quote, and post it for us. There may well be some detail that's been overlooked.

- Joined

- Dec 20, 2012

- Messages

- 9,422

I will, John, but not now. I just spent most of the day trying to get a building permit done so I can finish a shop extension and get a slab done. My lathe is pushed in a corner and I have no idea where my Cleve book is so this will go on the shelf. I cannot believe the BS involved in dealing with the City. Sorry, but I am in no mood for this right now.

B

British Steel

Forum Guest

Register Today

They had AOL in those days????

AOL seemed to be eternal, and their supply of throwaway discs infinite....

Dave H. (the other one)

- Joined

- Feb 17, 2013

- Messages

- 4,406

No problem ... mainly curiosity on my part. Best wishes dealing with the dadgum gummint bureaucracy!I will, John, but not now. I just spent most of the day trying to get a building permit done so I can finish a shop extension and get a slab done. My lathe is pushed in a corner and I have no idea where my Cleve book is so this will go on the shelf. I cannot believe the BS involved in dealing with the City. Sorry, but I am in no mood for this right now.