-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PROS/CONS 2 Piece Vise

- Thread starter jweaver72

- Start date

- Joined

- Jul 26, 2011

- Messages

- 4,142

I have had one of those too,for about 25 years without using it. If I were to use it,I'd place a large piece of paper under each end to avoid it slipping back on the smooth table of the mill. No doubt,clamping it down on a piece of metal would also involve smacking down the metal with a dead blow hammer while tightening.

- Joined

- Nov 17, 2013

- Messages

- 36

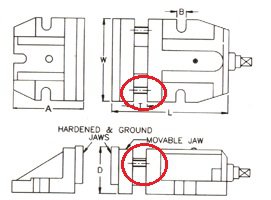

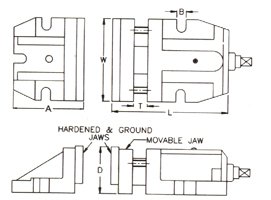

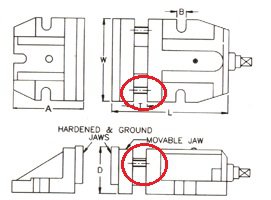

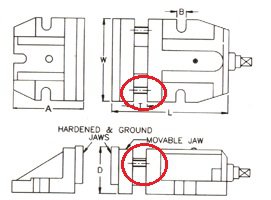

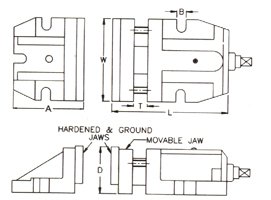

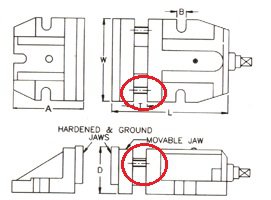

I wanted to add a few more pictures of various makes an models of 2pc vises. As with everything else there are different features from different manufactures.

I have pointed out the differences I feel are significant.

This vise has screws to back up the jaws as well as a groove in the base for quicker alignment.

This vise has screws to back up the jaws as well as a groove in the base for quicker alignment.

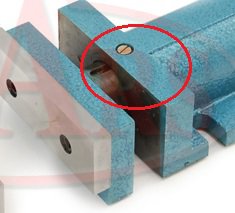

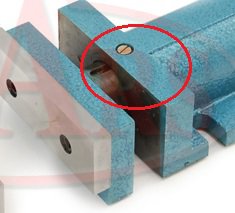

This one uses alignment pins

This one uses alignment pins

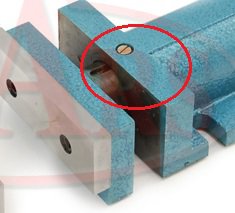

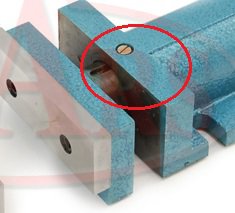

This one has a set screw that appears to be used as a gib

This one has a set screw that appears to be used as a gib

Screwless - I really like this one, but I would be concerned about it only having one clamping point per side.

Screwless - I really like this one, but I would be concerned about it only having one clamping point per side.

I have pointed out the differences I feel are significant.

This vise has screws to back up the jaws as well as a groove in the base for quicker alignment.

This vise has screws to back up the jaws as well as a groove in the base for quicker alignment. This one uses alignment pins

This one uses alignment pins This one has a set screw that appears to be used as a gib

This one has a set screw that appears to be used as a gib Screwless - I really like this one, but I would be concerned about it only having one clamping point per side.

Screwless - I really like this one, but I would be concerned about it only having one clamping point per side.

Last edited:

- Joined

- Jan 1, 2014

- Messages

- 9

Hey jweaver, BIG RED FLAG!!! You said earlier that you wouldn't have to dial it in, and that's going to BITE YOU, BIG TIME! Sooner or later you're going to want to mill a true edge, and most likely you'll have forgotten that your vise jaws really aren't dialed in, and you'll ruin your work. It sounds like you're looking at this setup as a permanent vise (in which case you really do want a Kurt style vise). This two piece style is meant to be a temporary vise to hold longer than normal work, for which a normal (or a gang of normal) vise(s) simply isn't big enough.

- Joined

- Nov 17, 2013

- Messages

- 36

You said earlier that you wouldn't have to dial it in, and that's going to BITE YOU, BIG TIME!

Coyotejake

I didn't remember saying that in this thread and I can not find it in the thread either. If I did say that somewhere along the line, I defiantly don't agree with it either. As a matter of fact I check my vise every time I used the machine.

Jweaver, the last picture of the vises {\rtf1\ansi\ansicpg1252

{\fonttbl}

{\colortbl;\red255\green255\blue255;}

}looks like a good design by pushing in & down @ the same time. I've actually thought about making a low profile table clamp with angled set screws that would push in & down @ the same time sort of like a low profile edge clamp. I remember fly cutting a piece of plate steel that was 12"x12"x 1 inch thick one time that I could not get in my Kurt vise.I can see a vice like this coming in handy from time to time. By the way what is the name on the tag of the last vice shown? I wanted to goggle it for more information.

Phil

Sorry the picture didn't show up but it's the last vise in your post.

{\fonttbl}

{\colortbl;\red255\green255\blue255;}

}looks like a good design by pushing in & down @ the same time. I've actually thought about making a low profile table clamp with angled set screws that would push in & down @ the same time sort of like a low profile edge clamp. I remember fly cutting a piece of plate steel that was 12"x12"x 1 inch thick one time that I could not get in my Kurt vise.I can see a vice like this coming in handy from time to time. By the way what is the name on the tag of the last vice shown? I wanted to goggle it for more information.

Phil

Sorry the picture didn't show up but it's the last vise in your post.

Last edited:

- Joined

- Nov 17, 2013

- Messages

- 36

By the way what is the name on the tag of the last vice shown? I wanted to goggle it for more information.

It is made by Apex and I have been unable to find a source to purchase it myself. If you find a place to get it please share.

Thanks

http://apexmachinevices.com/736.html

- Joined

- Dec 3, 2012

- Messages

- 17

Looking for a little advice on 2 piece vises for milling operations.

I have a Grizzly Tools version of this vise and use it all the time.

It certainly will not take the place of a good one piece vise, but if you have large items, it works very well.

My situation may be different than yours however.

I mill and drill and tap large thick pieces and rather than using hold downs all over, I just space the vise halves 40 inches apart and hold the short ends in the vise.

A piece of stock needs to be placed under the work or it will deflect in that length.

Tramming is not an issue for me, but it may be for you.

I bolt down the fixed end of the vice fairly close to square with the table and then leave the other end of the vise lightly tightened down to the table.

The work is place between the two halves, the movable jaw is lightly snugged to the work, then the vise is tightened to the table and the work is now square to the vise (but not necessarily to the machine.)

I have a Centroid CNC with the Parts Coordination software so with two touches of the probe, the part is auto-trammed to the machine.

Tramming and squaring a two piece vise otherwise, will not be fun.

On the other hand, since the vise is two piece, you can hold items where the two ends are not perfectly parallel to each other.

The jaws do not care that they are at a 5 degree angle to each other.

I also mill big round things. Using an angle plate and the fixed end at two locations and the movable jaw at the opposite end, is a great way to secure the parts.

Much faster than clamps.

Everything is just another tool.

- Joined

- Jan 1, 2014

- Messages

- 9

Coyotejake

I didn't remember saying that in this thread and I can not find it in the thread either. If I did say that somewhere along the line, I defiantly don't agree with it either. As a matter of fact I check my vise every time I used the machine.

You're right. You were mentioning something about the ways being true, and I jumped to a conclusion (so THAT'S how she does it!). Anyway, I was worried about you setting yourself up for a mistake. My apologies. I've been wondering if I might need one of those sets in case a 'bigger' job comes along.

- Joined

- Nov 17, 2013

- Messages

- 36

I mill and drill and tap large thick pieces and rather than using hold downs all over, I just space the vise halves 40 inches apart and hold the short ends in the vise.

Denny

Thanks for the great info.

In another post I read that using this type of vise, especially with long material, will warp your table. Have you experienced any of this?