- Joined

- Apr 20, 2014

- Messages

- 34

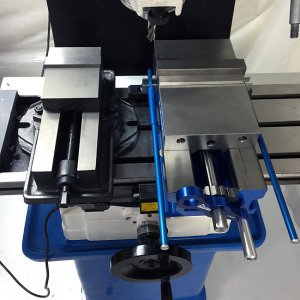

Vise

I had read a few postings on the issue about the 6" being too big. I have seen the Kurt D688 several times and it's a monster indeed. On youtube I did stumble on someone using a D688 on his PM45 but it takes up every inch of space and more. Would never go that route. It's 16.81" long / 8.28" wide / 4.61" height / 1.93" for the hex sticking out. There's the D40 I was looking at (12.34" long / 5.75" wide / 3.485" height / 1.93" hex). I was also looking at the Glacern 5" (14.5" long / 7.625" wide / 4.1" height / 1.8" hex). I do know I need something bigger. I'm not worried about weight as I rarely have to remove the vise, as everything I do needs a vise.

I had read a few postings on the issue about the 6" being too big. I have seen the Kurt D688 several times and it's a monster indeed. On youtube I did stumble on someone using a D688 on his PM45 but it takes up every inch of space and more. Would never go that route. It's 16.81" long / 8.28" wide / 4.61" height / 1.93" for the hex sticking out. There's the D40 I was looking at (12.34" long / 5.75" wide / 3.485" height / 1.93" hex). I was also looking at the Glacern 5" (14.5" long / 7.625" wide / 4.1" height / 1.8" hex). I do know I need something bigger. I'm not worried about weight as I rarely have to remove the vise, as everything I do needs a vise.

Last edited: