- Joined

- Jan 28, 2011

- Messages

- 3,486

Re: PM 1236 Sheave Mod and Dog Clutch from Hi/Lo range

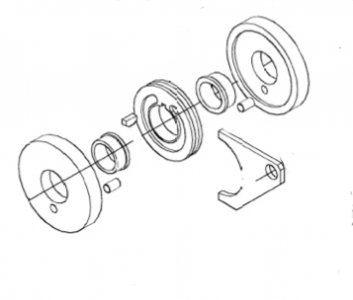

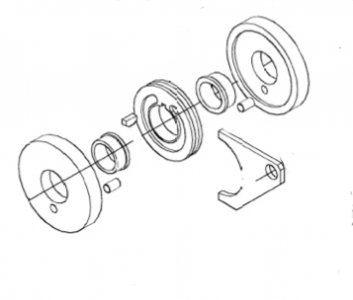

I came up with a slightly better idea then what I originally had, during the day, borrowed from the dog clutch people. If I was to make new motor pulley that has a seperation of about 3/8 to 1/2" and do the same, but in two seperate and running on bearing, at the top countershaft pulley, I can insert a dog clutch between them on the countershaft. A simple push/pull knob to engage either pulley and away you go. Low or High speed and with a VFD you do not have to run the HZ too far from 60, maybe from 30 to 90 or even tighter. I have not sat down to figure the ratios.

Pierre

I came up with a slightly better idea then what I originally had, during the day, borrowed from the dog clutch people. If I was to make new motor pulley that has a seperation of about 3/8 to 1/2" and do the same, but in two seperate and running on bearing, at the top countershaft pulley, I can insert a dog clutch between them on the countershaft. A simple push/pull knob to engage either pulley and away you go. Low or High speed and with a VFD you do not have to run the HZ too far from 60, maybe from 30 to 90 or even tighter. I have not sat down to figure the ratios.

Pierre