- Joined

- Feb 13, 2017

- Messages

- 2,138

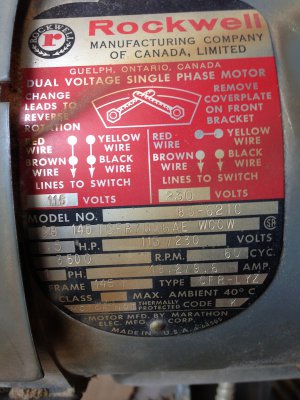

The diagram shown should be enough. It is very direct. The line cord has two functional conductors. The third is a ground, attaching to any convenient metal part of the motor. As a rule, 120V circuits are set up where L1 is the hot, or black wire. L2 is the neutral, or white wire. The Ground, or green wire goes to the motor frame. The important issue is with the dual voltage connections. T2 and T8 connecting to Terminal [4]. T3 and T5 connecting to Terminal [2]. Terminal [3] is left open, no connection.

The diagram doesn't show rated current. Converting to 120V will effectively double the current. The line cord should be a minimum of AWG14, preferably AWG12 or larger. I personally like long line cords and usually make them out of half of an "industrial" 25 ft extension cord. A fairly inexpensive source for molded plugs. . . The AWG wire size is usually printed(heat stamped) at regular intervals along the cable jacket.

The circuit supplying the saw must also be capable of handling the high current. The saw was wired for 240 volts for a reason. They usually come pre-wired from the factory for 120 volts unless they are commercial grade. You may do well to stick with the 240 volt wiring. Depending on the location among other factors, "borrowing" a tap from a dryer or range plug may provide a temporary outlet.

If there is a starter or contactor on board, the overload "heaters" will need changing also. Stash the old ones in a plastic bag taped inside the starter enclosure so they can be found easily if needed. That low of HP motor likely doesn't have any, but the previous owner may have put one on. If it is magnetic, the coil will need changing also.

.

The diagram doesn't show rated current. Converting to 120V will effectively double the current. The line cord should be a minimum of AWG14, preferably AWG12 or larger. I personally like long line cords and usually make them out of half of an "industrial" 25 ft extension cord. A fairly inexpensive source for molded plugs. . . The AWG wire size is usually printed(heat stamped) at regular intervals along the cable jacket.

The circuit supplying the saw must also be capable of handling the high current. The saw was wired for 240 volts for a reason. They usually come pre-wired from the factory for 120 volts unless they are commercial grade. You may do well to stick with the 240 volt wiring. Depending on the location among other factors, "borrowing" a tap from a dryer or range plug may provide a temporary outlet.

If there is a starter or contactor on board, the overload "heaters" will need changing also. Stash the old ones in a plastic bag taped inside the starter enclosure so they can be found easily if needed. That low of HP motor likely doesn't have any, but the previous owner may have put one on. If it is magnetic, the coil will need changing also.

.