- Joined

- Sep 8, 2019

- Messages

- 4,392

Not in the bay area, Minnesota. First off let me tell you how it happens "on the job". Your set up with gap and land looks fine, you have surely found out by now that pipe is not round! If your coupons both come from the same length of pipe it makes it easy to line them up and deal with ovality, otherwise rotate them to get your best fit - up.

On schedule #40 pipe the root pass is done with 1/8" 6010, not 3/32". never a downhill root on pressure piping 12" diameter or less always uphill, less chance of slag inclusions.

The hot pass will either be done with, depending on the prescribed weld procedure, 1/8" 6010 or 3/32" 7018, both will be run uphill.

The cover pass will be run with, also depending on the prescribed procedure, 1/8" 6010 or #/32" 7018, both will be uphill as well.

The reason for 1/8" 6010 and 3/32" 7018 is that both can be run at the same amperage (about 90 for starters). You don't want to have to jump out of the ditch and run back to your welder to adjust amps between the root and hot pass and cover pass. Minor amperage adjustments are accomplished by varying travel speed and arc length, you will get used to it.

Just a couple of observations. You have to hurry so fast with your root because you are using 3/32", 1/8" will deposit more filler material at a slower travel speed. You are "outclassed" by 1/8'' 7018 in a small bevel. The hot pass should be level with the parent metal and the top edges of the bevel should be visible and not eroded. When doing the cover pass the electrode should hesitate centered on the edge of the bevel long enough to fill the puddle and then move one electrode diameter uphill and hesitate on the opposite bevel.

I am not just picking these rod diameters out of thin air, they are the industry standard and will be the same for every test. Stringer beads will be used on horizontal welds for the cover pass. You have to have patience and walk before you can run. I wish I could spent a few hours with you in a welding booth.

So no downhill welding on the root. Got it. I see that I continue to do more things wrong than right.

So the cover pass is a single bead (maybe a weave)? My cover passes have 2 beads. I will post a photo.

I did not understand “outclassed” (by 7018). You mean the 1/8” should be 3/32”?

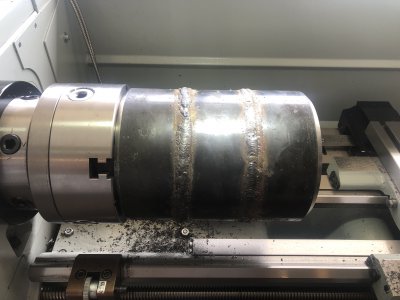

I did see that pipe is not round. Mine is even less so because it has been tightly clamped in a 12” 4J independent to make the coupon.

I am going to need to figure out a way to tack the pipe that minimizes ovality and yields a more consistent gap. I was trying to gap to 1/16”, and I ended up with up to 1/8”. Very tough to lay a root in a 1/8” gap with a 3/32” rod.

Finally (for now), the lands on my coupons are not consistent. This is due to the 4J independent chuck distorting the pipe. I need to have the jaws tight because I am clamping the work from the inside & I don’t want the workpiece to fly out (as has happened with 4” pipe in a 3J universal chuck which is exciting). What size land should I aim for? I tried for .050” which burns away pretty quickly with 3/32” 6010 at 50 to 60 Amps.

Last edited: