- Joined

- Apr 10, 2021

- Messages

- 593

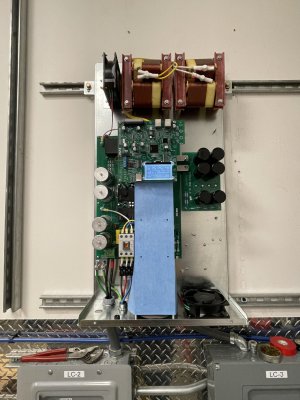

The 10 and 20 hp are the old blue ones I bought usedthat are no longer supported. The newest is the 30 hp white model about 5 years old so predates their newer alternatives. If I were buying today I'd suck it up and opt for the higher end model. I know how reliable they are. Dave