- Joined

- Nov 23, 2020

- Messages

- 787

Hi all,

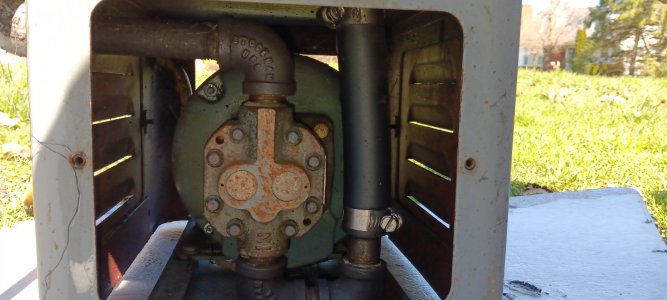

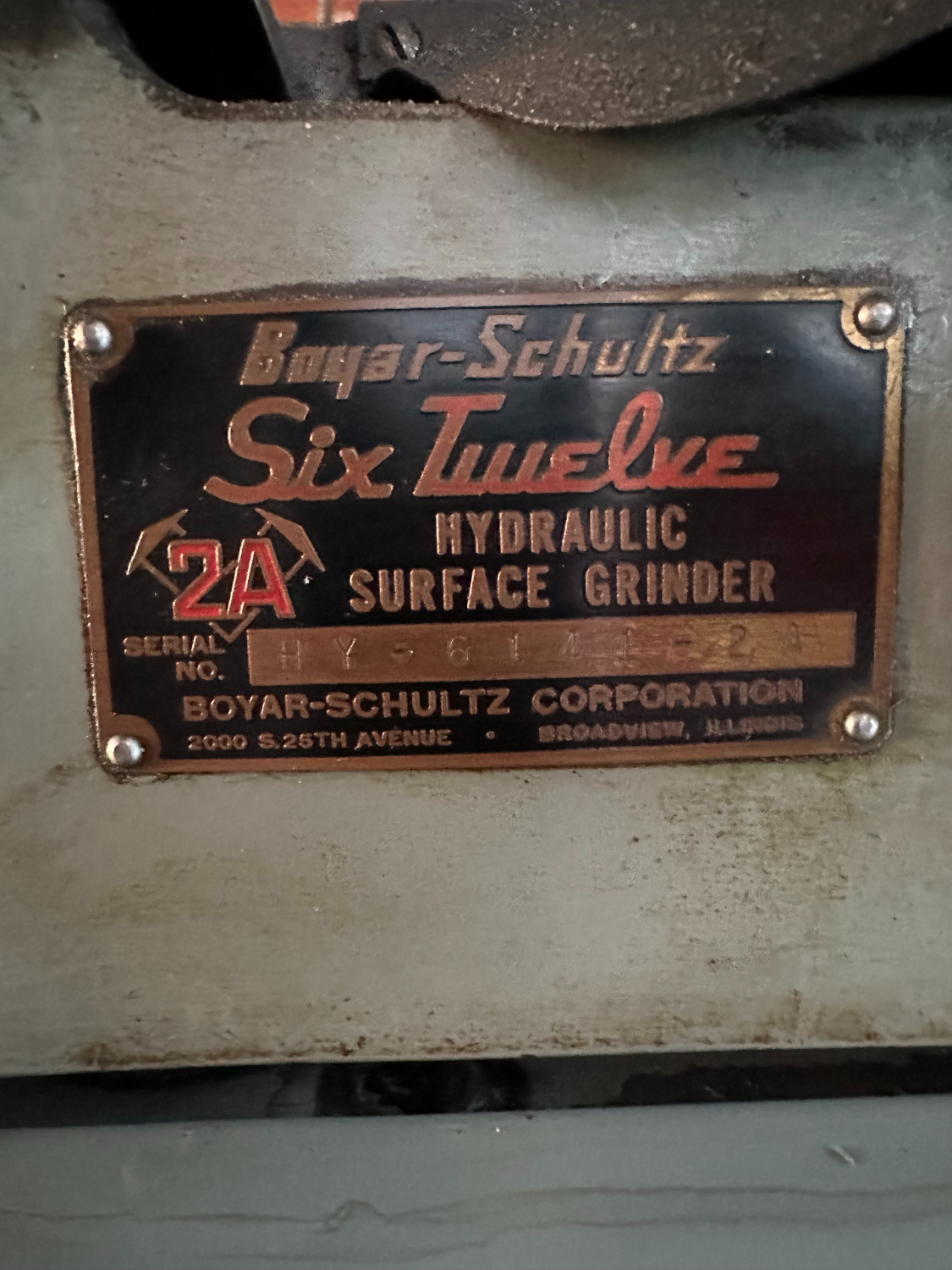

Picked up a new machine this past weekend. Anyone able to assist in any docs that may be relevant to this machine? It is set up for hydraulic table, but did not come with pump...so I will eventually like to sort that, but the machine can be used manually as well.

Any ideas on year of manufacture? I am in process of disassembly and cleaning. The chrome ways look fantastic, and the table ways look incredible for the machines age. Will send more pics on that.

Picked up a new machine this past weekend. Anyone able to assist in any docs that may be relevant to this machine? It is set up for hydraulic table, but did not come with pump...so I will eventually like to sort that, but the machine can be used manually as well.

Any ideas on year of manufacture? I am in process of disassembly and cleaning. The chrome ways look fantastic, and the table ways look incredible for the machines age. Will send more pics on that.