-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New PM-1228 Joins the Crew

- Thread starter AlanB

- Start date

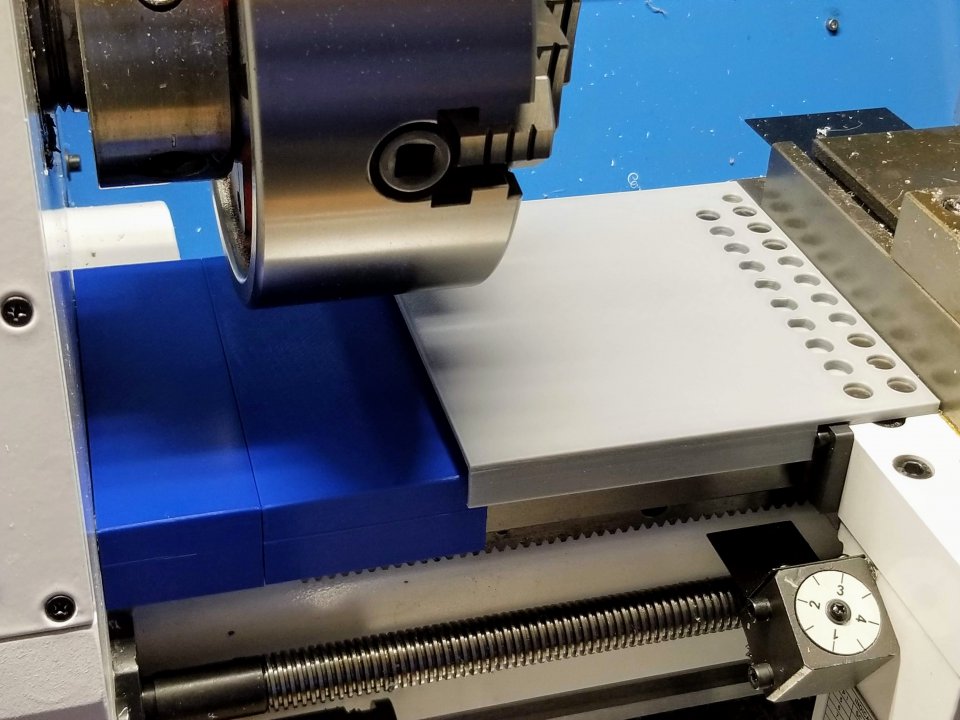

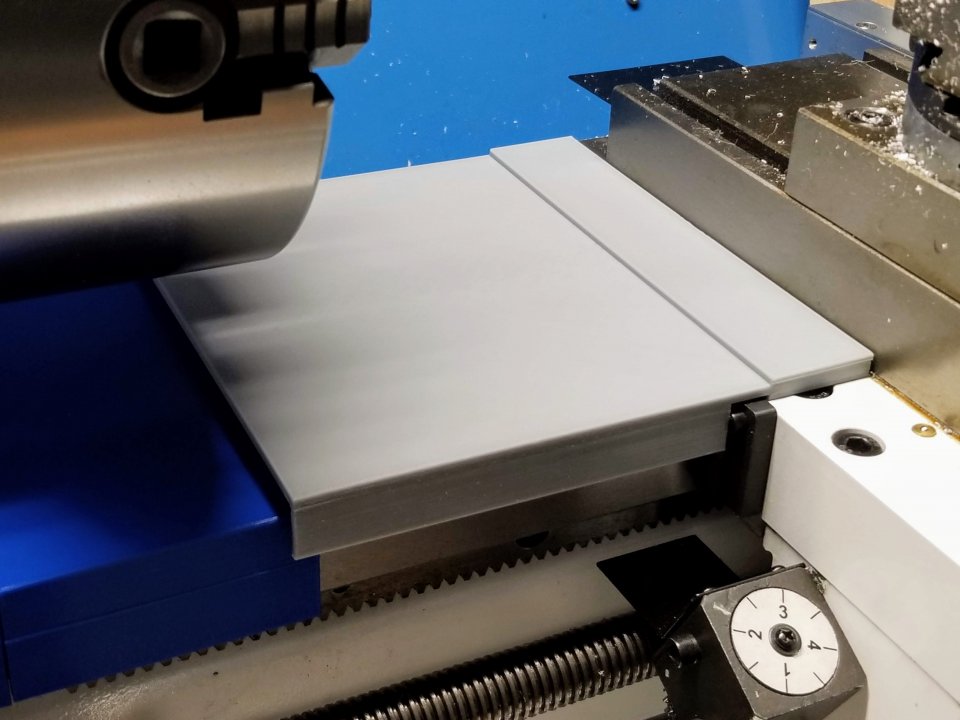

Here is the first full size prototype. Telescopes nicely over the way covers and looks like it will do the job. Stays out of the way when the carriage is fully retracted. More magnets can be used to hold it if desired. Will make a top cover to keep the magnets in and the swarf away from the magnets. If hot chips are anticipated a thin aluminum sheet over the top would be prudent.

This cover has dimples underneath matching the magnet holes to help keep it in place. I'll cement it on after I have decided how many magnets to use. If I cement the top and not the magnets themselves I can split it off to recover the magnets when it is no longer used. This setup telescopes for a useful length of about 120mm. I can print more sections of the way covers to lay in when working farther from the chuck. Perhaps I should consider adding more coverage in the front to protect the leadscrew with this system. Another possible improvement is to print some locating tabs underneath that index to the carriage in the X direction. There's always an improvement that can be made.

This cover can easily be lifted off when the follow rest is desired, or to reach the rear oiler.

This cover can easily be lifted off when the follow rest is desired, or to reach the rear oiler.

It doesn't look like I mentioned it earlier in this thread (or I missed it in a quick review), but when I used the turns counter together with the DRO to measure lathe travel to verify some gear ratios they came out wrong. I sent some data to Precision Matthews, and they instantly suggested counting the teeth on the 90 tooth gear. I did so (using a photograph printed on a sheet of paper) and sure enough there was an extra tooth on that gear marked Z90. They have seen this on a few lathes, a mismarked gear. They had just run out of that gear at the time (May) and I've just now received the replacement (and verified the tooth count). Good service. Something to be aware of, easy enough to check with a caliper or DRO on your lathe.

- Joined

- Sep 8, 2019

- Messages

- 4,392

It doesn't look like I mentioned it earlier in this thread (or I missed it in a quick review), but when I used the turns counter together with the DRO to measure lathe travel to verify some gear ratios they came out wrong. I sent some data to Precision Matthews, and they instantly suggested counting the teeth on the 90 tooth gear. I did so (using a photograph printed on a sheet of paper) and sure enough there was an extra tooth on that gear marked Z90. They have seen this on a few lathes, a mismarked gear. They had just run out of that gear at the time (May) and I've just now received the replacement (and verified the tooth count). Good service. Something to be aware of, easy enough to check with a caliper or DRO on your lathe.

That is very impressive that you detected that error!

I measured the 24 TPI threading travel with the DRO and 24 rotations of the spindle (carefully positioning the chuck, with the slack removed) which produced 0.989 inches of travel, which is 24.27 TPI. I verified the DRO with a dial indicator. I made other measurements as well to verify the error. Having a turns counter on the chuck and the DRO made it pretty easy to do the measurements.