I have been looking at a lathe upgrade for a few years, and finally the stars aligned. The PM-1228VF-LB is replacing a 10x21 that I've been using for a very long time. It has been doing the job but I wanted more features. I could write a lot about the selection process, but as with most things, this is a good compromise between what I need and what I want and what I actually have room and budget for. It's also about as much as 120V can provide, and minimizes the startup projects.

Picking it up at the depot on my utility trailer works better than trying to deal with a delivery, and that went fine. They forklifted the double palleted box onto the trailer and I strapped it down and brought it home. Transferring the 490 pound machine to the workbench was the next challenge. The tailstock and chuck were removed but that doesn't help a lot on this machine. The scheme we came up with was to position a hydraulic lift table across the end of the workbench, and back the trailer through the garage door and right up to the lift table. Unfortunately I didn't stop to take pictures, we were rather busy focusing on the task at hand. The procedure was to slide (two people pushing accomplished this) the stacked pallets onto the hydraulic table which had been matched to the trailer height. The trailer was stabilized by the 3/4 ton truck it was still connected to, and about 1/3 of the pallet fit onto the hydraulic table. The pallets were then elevated so the lathe was at workbench height by alternately raising the hydraulic table and a floor jack on the trailer under the tailstock end of the pallets. The pallets were kept level through the process. We used a 2x4 lever to get the floor jack under the pallets, but lifting was all hydraulic thereafter. The hydraulic table kept the pallet level on the lathe's X axis, and the floor jack was matched to the table's height keeping the Z axis level. Once the top of the pallets was at workbench level the attachment bolts from lathe to pallet were removed. A pair of rollers cut from closet rod were levered under the headstock foot and the lathe was rolled and tailstock slid a few inches at a time, moving the rollers to keep one under the fairly short foot, onto the workbench and into position. The rollers were finally removed using wood levers.

The chip pan is not under the lathe yet, that will be a future project. I'm not sure if this workbench will be the final support. I'm thinking a small gantry crane might be useful to have around and this workbench might be upgraded to something with drawers as I did on the PM-728 mill earlier.

The lathe arrived in good condition, there are a few scrapes and the usual paint chips, but overall it is good. The plastic tool chest is badly cracked and useless, but apparently that is the norm.

In any case we're operational. I installed the AXA Toolpost and topped up the oil. I picked up a 150 ml syringe and use that for putting in the oil. I overfilled it, so I removed the sight glass to let the extra out rather than drain the whole thing. That worked well, but I discovered something on the threads of the sight glass which appears to be teflon tape. This makes no sense as there is a gasket and these are not sealing threads. In any case the proper oil level has been reached.

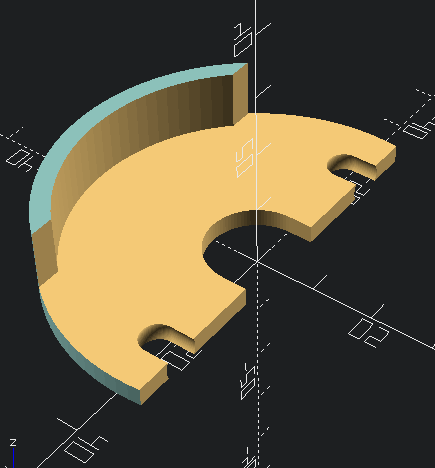

The gearbox is shifting a bit rough and uncertain. I know that it needs to be run at low speed, or the chuck rocked to align the gears, but it seems to be a little tricky to find the gear. The manual suggests using a sharpie to better mark the knob skirt. The knobs were very dirty, so I removed them to clean them and the ball bearing detents fell out. I didn't lose anything, but reassembly is a bit tricky. So I designed and 3d printed a tool to hold the balls in alignment while the knobs are being reinstalled. The small slots hold the balls in position while the central slot rides under the shaft keeping the jig in the right spot. Once the knob springs push on the balls and hold them in place the tool can be withdrawn. That worked out nicely.

But the shifting is still a bit difficult, sometimes it seems to want to be slightly off the marks in some gears. I wonder if I should slightly chamfer the holes in the face of the lathe to make the ball detents more positive, or ? Any suggestions??

I had some trouble getting the Feed and Cross Feed shifting engaged - it sometimes locks out and never engages. It turns out that the Halfnut lever has more than 2 positions. Engaged, Disengaged, and a little beyond that is Too Far Disengaged. In the Too Far Disengaged position it locks out the Feed and Cross Feed. Is there a fix for that? It can be worked around of course.

One of the tasks that I use the lathe for is winding line onto some reels that I 3D print. I use a turns counter to measure the line with appropriate calculations for the reel circumference, accounting for the change as it fills. To do this I use a magnet on the spindle and an LCD counter that I 3d printed a mount for. This used magnets to stick to the top of the old lathe. Well, the top of this new lathe is plastic, and I wanted to get this counter further back and out of the way anyhow, so I designed a new mount setup for this. The magnets are on the side now, and it is back out of the way of the chuck key and tool area that might be in use. Another problem solved with a little 3d printing. This is the prototype but it is working so well I haven't printed up a more final version.

Well, that's most of the story so far. I made a few chips and am starting to get used to having a DRO which is a nice improvement. I would like to put an Electronic Leadscrew on this someday, but it is not a priority. With 15 speed gearbox this covers most imperial threads without gear changes, and it gives a good range of feed rates. I like the brushless DC motor, though the speed pot only goes down to 50 RPM. I'm used to a speed pot that goes to zero. When winding line on a reel this means I have to push a button to stop it, rather than just using the knob. It stops very quickly especially from low speeds, and we don't wind at high speeds anyway, so it is manageable.

I did a quick test and a "D" Maglite will fit in the bore of the PM-1228. Just in case you need to turn, thread, or modify any of your Maglites.

Thanks in advance for any comments and suggestions,

AlanB

Picking it up at the depot on my utility trailer works better than trying to deal with a delivery, and that went fine. They forklifted the double palleted box onto the trailer and I strapped it down and brought it home. Transferring the 490 pound machine to the workbench was the next challenge. The tailstock and chuck were removed but that doesn't help a lot on this machine. The scheme we came up with was to position a hydraulic lift table across the end of the workbench, and back the trailer through the garage door and right up to the lift table. Unfortunately I didn't stop to take pictures, we were rather busy focusing on the task at hand. The procedure was to slide (two people pushing accomplished this) the stacked pallets onto the hydraulic table which had been matched to the trailer height. The trailer was stabilized by the 3/4 ton truck it was still connected to, and about 1/3 of the pallet fit onto the hydraulic table. The pallets were then elevated so the lathe was at workbench height by alternately raising the hydraulic table and a floor jack on the trailer under the tailstock end of the pallets. The pallets were kept level through the process. We used a 2x4 lever to get the floor jack under the pallets, but lifting was all hydraulic thereafter. The hydraulic table kept the pallet level on the lathe's X axis, and the floor jack was matched to the table's height keeping the Z axis level. Once the top of the pallets was at workbench level the attachment bolts from lathe to pallet were removed. A pair of rollers cut from closet rod were levered under the headstock foot and the lathe was rolled and tailstock slid a few inches at a time, moving the rollers to keep one under the fairly short foot, onto the workbench and into position. The rollers were finally removed using wood levers.

The chip pan is not under the lathe yet, that will be a future project. I'm not sure if this workbench will be the final support. I'm thinking a small gantry crane might be useful to have around and this workbench might be upgraded to something with drawers as I did on the PM-728 mill earlier.

The lathe arrived in good condition, there are a few scrapes and the usual paint chips, but overall it is good. The plastic tool chest is badly cracked and useless, but apparently that is the norm.

In any case we're operational. I installed the AXA Toolpost and topped up the oil. I picked up a 150 ml syringe and use that for putting in the oil. I overfilled it, so I removed the sight glass to let the extra out rather than drain the whole thing. That worked well, but I discovered something on the threads of the sight glass which appears to be teflon tape. This makes no sense as there is a gasket and these are not sealing threads. In any case the proper oil level has been reached.

The gearbox is shifting a bit rough and uncertain. I know that it needs to be run at low speed, or the chuck rocked to align the gears, but it seems to be a little tricky to find the gear. The manual suggests using a sharpie to better mark the knob skirt. The knobs were very dirty, so I removed them to clean them and the ball bearing detents fell out. I didn't lose anything, but reassembly is a bit tricky. So I designed and 3d printed a tool to hold the balls in alignment while the knobs are being reinstalled. The small slots hold the balls in position while the central slot rides under the shaft keeping the jig in the right spot. Once the knob springs push on the balls and hold them in place the tool can be withdrawn. That worked out nicely.

But the shifting is still a bit difficult, sometimes it seems to want to be slightly off the marks in some gears. I wonder if I should slightly chamfer the holes in the face of the lathe to make the ball detents more positive, or ? Any suggestions??

I had some trouble getting the Feed and Cross Feed shifting engaged - it sometimes locks out and never engages. It turns out that the Halfnut lever has more than 2 positions. Engaged, Disengaged, and a little beyond that is Too Far Disengaged. In the Too Far Disengaged position it locks out the Feed and Cross Feed. Is there a fix for that? It can be worked around of course.

One of the tasks that I use the lathe for is winding line onto some reels that I 3D print. I use a turns counter to measure the line with appropriate calculations for the reel circumference, accounting for the change as it fills. To do this I use a magnet on the spindle and an LCD counter that I 3d printed a mount for. This used magnets to stick to the top of the old lathe. Well, the top of this new lathe is plastic, and I wanted to get this counter further back and out of the way anyhow, so I designed a new mount setup for this. The magnets are on the side now, and it is back out of the way of the chuck key and tool area that might be in use. Another problem solved with a little 3d printing. This is the prototype but it is working so well I haven't printed up a more final version.

Well, that's most of the story so far. I made a few chips and am starting to get used to having a DRO which is a nice improvement. I would like to put an Electronic Leadscrew on this someday, but it is not a priority. With 15 speed gearbox this covers most imperial threads without gear changes, and it gives a good range of feed rates. I like the brushless DC motor, though the speed pot only goes down to 50 RPM. I'm used to a speed pot that goes to zero. When winding line on a reel this means I have to push a button to stop it, rather than just using the knob. It stops very quickly especially from low speeds, and we don't wind at high speeds anyway, so it is manageable.

I did a quick test and a "D" Maglite will fit in the bore of the PM-1228. Just in case you need to turn, thread, or modify any of your Maglites.

Thanks in advance for any comments and suggestions,

AlanB

Last edited: