- Joined

- Sep 25, 2012

- Messages

- 302

<ST1 I just received the DRO today. It was delayed several days because one of the scales that I had requested was out of stock and It took an additional 7 days to reach my hose from <st1:country-region w:st="on"><ST1

I just received the DRO today. It was delayed several days because one of the scales that I had requested was out of stock and It took an additional 7 days to reach my hose from <st1:country-region w:st="on"><ST1 Singapore</ST1

Singapore</ST1 </st1:country-region>. Pretty good time considering these were the places it visited.<O

</st1:country-region>. Pretty good time considering these were the places it visited.<O </O

</O

<st1:country-region w:st="on"><ST1 Singapore</ST1

Singapore</ST1 </st1:country-region><O

</st1:country-region><O </O

</O

Sennan <st1:country-region w:st="on"><ST1 Japan</ST1

Japan</ST1 </st1:country-region><O

</st1:country-region><O </O

</O

Beijiang <st1:country-region w:st="on"><ST1 China</ST1

China</ST1 </st1:country-region><O

</st1:country-region><O </O

</O

Incheon South <st1:country-region w:st="on"><ST1 Korea</ST1

Korea</ST1 </st1:country-region><O

</st1:country-region><O </O

</O

<ST1 <st1:City w:st="on">Anchorage</st1:City> <st1:State w:st="on">Alaska</st1:State></ST1

<st1:City w:st="on">Anchorage</st1:City> <st1:State w:st="on">Alaska</st1:State></ST1 <O

<O </O

</O

<ST1 <st1:City w:st="on">Memphis</st1:City> <st1:State w:st="on">Tennessee</st1:State></ST1

<st1:City w:st="on">Memphis</st1:City> <st1:State w:st="on">Tennessee</st1:State></ST1 <O

<O </O

</O

<ST1 <st1:City w:st="on">Norfolk</st1:City> <st1:State w:st="on">Virginia</st1:State></ST1

<st1:City w:st="on">Norfolk</st1:City> <st1:State w:st="on">Virginia</st1:State></ST1 <O

<O </O

</O

It was well packed, had no damage and I never received a call from customs.<O </O

</O

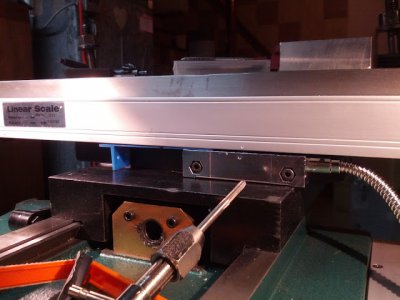

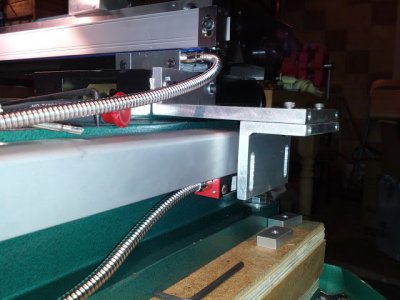

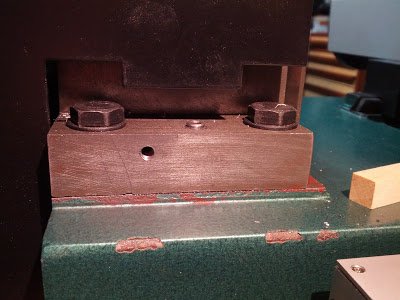

I am very impressed with the quality of scales and readout so far and neither look cheaply made.

I look forward to your write up of the installation and operation. Chuck

<st1:country-region w:st="on"><ST1

Sennan <st1:country-region w:st="on"><ST1

Beijiang <st1:country-region w:st="on"><ST1

Incheon South <st1:country-region w:st="on"><ST1

<ST1

<ST1

<ST1

It was well packed, had no damage and I never received a call from customs.<O

I am very impressed with the quality of scales and readout so far and neither look cheaply made.

I look forward to your write up of the installation and operation. Chuck