yeah, he has some good simple videos which only shows how easy and simple running those tasks is with a DRO. almost takes the fun out of the scratching your head thinking "now what?" or "how many turns did I just turn the wheel?!?" :thinking:

anywhoo...

With the hole locating block made earlier It was easy to mark and drill the mounting holes for the M5(scale) and M4(cover) using a #19, and #60 drill bits respectively. I originally didn't like the idea of mounting the scale onto the black table cap which houses the screw bracket and all as it isn't flush with the table, and has all the bolts holding it to the table, but after thinking about it decided to go ahead with it as otherwise I would have to mill some extension block (AL) on the other side of the table since the scale is a tad bit too long to be otherwise mounted. the hole in the black cap goes all the way to the bolt that holds the cap to the table- just be careful not to drill through the bolt

I tapped the holes, and it seems like my cheapo taps were eaten alive by the CI table.. might need to place an order for better quality taps in those sizes. I may be able to complete this install with current taps, but it's questionable, and I would probably have to dump them at some point.

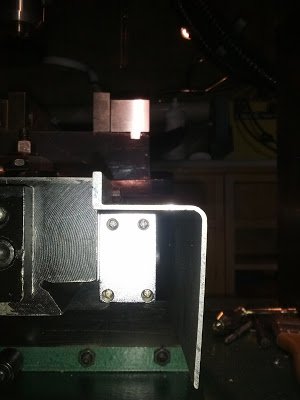

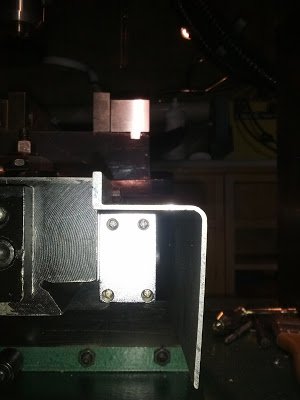

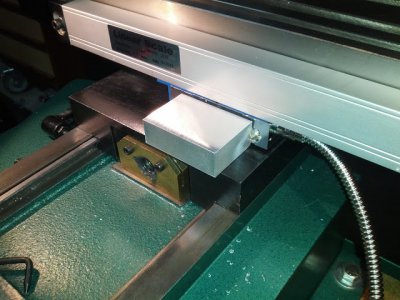

the placement of everything seems very pleasing so far (non operational stage):

and there is about 1+mm of spacing between scale and cover (doesn't show too well in pic, but it's nice and visible and parallel throughout:

I still have to remove cover, and install the reader itself, but it started to get late, and I decided to continue when I have better focus.

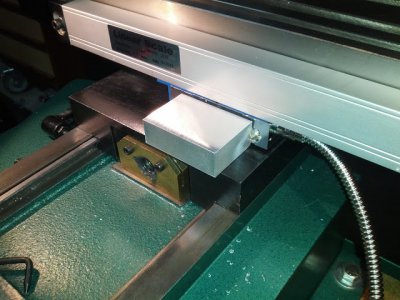

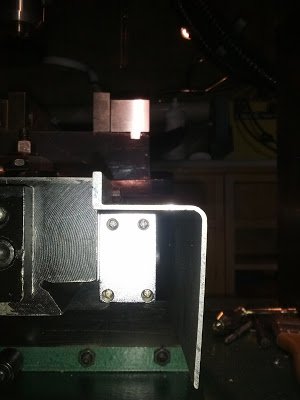

But I did wanted to do a bit more, so I installed the DRO keypad on the column. At first I questioned the stiffness of the column cover to hold the arm and the keypad, but the keypad itself is fairly lightweight, and the column cover seems to be made out of pretty thick quality sheet metal (1/8" thick or so) and was tapped to take the M5 bolts, and seems to have 0 flex in it and holes things very well:

So... next step would be to install the X-reader, followed by testing the X axis, and installing the Y, and Z there after... one step at a time. so far so good.