-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Dragon 14x40 Lathe Photos, VFD, Wiring, and Questions.

- Thread starter aluminum

- Start date

- Joined

- Jan 7, 2016

- Messages

- 3,279

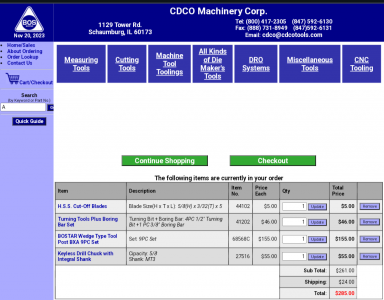

I have a 12x40 lathe and use a BXA tool post and holders on mine. I purchased them from http://www.cdcotools.com. I know that some may groan at buying such an inexpensive tool post and holders, but seriously, it has one job to do and that is to hold the cutting tool. Mine works fine and I can't hardly make the tool holders for what they sell them for.

If that VFD has a fan it, just cut some holes in the sides and bottom which will provide for sufficient air flow. If the VFD does not have a fan it, I would pick up a 40mm computer fan and mount it in the bottom. There should be a 12 or 24 volt leg on that VFD that you can pull from. I 3D printed louvers for my VFD enclosure on my Sharp mill.

If that VFD has a fan it, just cut some holes in the sides and bottom which will provide for sufficient air flow. If the VFD does not have a fan it, I would pick up a 40mm computer fan and mount it in the bottom. There should be a 12 or 24 volt leg on that VFD that you can pull from. I 3D printed louvers for my VFD enclosure on my Sharp mill.

- Joined

- Jan 7, 2016

- Messages

- 3,279

Tool holders on eBay. You may end up replacing the set screws, but they should work fine.

eBay tool holders

One of our members here (@davidpbest) has written a rather useful book on insert tooling. I highly recommend it. Introduction to Insert Lathe Tooling

Also... http://www.hobby-machinist.com/forums/david-p-best-selected-resources-for-machinists.597/

David also has an extensive list of tooling sources and such, but I can't find it at the moment.

eBay tool holders

One of our members here (@davidpbest) has written a rather useful book on insert tooling. I highly recommend it. Introduction to Insert Lathe Tooling

Also... http://www.hobby-machinist.com/forums/david-p-best-selected-resources-for-machinists.597/

David also has an extensive list of tooling sources and such, but I can't find it at the moment.

Last edited:

- Joined

- Dec 9, 2021

- Messages

- 735

With QCTP's there are trade-offs, like most other things. Bigger is more rigid, but is more cumbersome. Rigid can be better, but if the lathe isn't sturdy enough to take advantage of it, there is no payoff.

50 years ago, we were using brazed-point carbide bits on WWII-era machines. A 1/2" bit was tough enough to use on a 20HP lathe, and with flood coolant you could take 1/2" off a side using 1140 steel. When insert bits became affordable, the bits and holders got larger, and there was an increase in productivity, but not a spectacular one. For a home shop, the trade-off is more about getting the bit properly aligned with the work than taking the most material in a cut.

50 years ago, we were using brazed-point carbide bits on WWII-era machines. A 1/2" bit was tough enough to use on a 20HP lathe, and with flood coolant you could take 1/2" off a side using 1140 steel. When insert bits became affordable, the bits and holders got larger, and there was an increase in productivity, but not a spectacular one. For a home shop, the trade-off is more about getting the bit properly aligned with the work than taking the most material in a cut.

- Joined

- Sep 25, 2014

- Messages

- 1,111

You have a 4 position turret tool post, nothing wrong with just using it. Make yourself a nice selection of shims that fit well (avoid a stack of cards, after a while you will have a goto selection), it is quick to set up a makes for a bit more rigid set up (you can keep the tool in a bit closer to the compound, if you want to).

I have changed to Qctp (first one was PhaseII wedge, the next two were 40P Multifix style), but the first 35 years I used the 4 way turret - it is not a bad arrangement. As for what style Qctp? Having used two of the common systems, my preference is for the 40P Multifix over the Aloris style (not a big enough deal that I’d replace the PhaseII system).

About the handle position, put a washer under it, or skim a little bit off the contact face (obviously keep it away from the chuck) to bring it around to a comfortable orientation.

Good luck with the new machine.

I have changed to Qctp (first one was PhaseII wedge, the next two were 40P Multifix style), but the first 35 years I used the 4 way turret - it is not a bad arrangement. As for what style Qctp? Having used two of the common systems, my preference is for the 40P Multifix over the Aloris style (not a big enough deal that I’d replace the PhaseII system).

About the handle position, put a washer under it, or skim a little bit off the contact face (obviously keep it away from the chuck) to bring it around to a comfortable orientation.

Good luck with the new machine.

- Joined

- Sep 25, 2014

- Messages

- 1,111

It looks like the bolt is in a T-slot, can you slide it out and try it turned round 180?Thanks! I'll look into the items you mentioned. I have a washer in there now to keep the handle pointing away from the chuck. I thought there might be a more integrated way. Thank you again!

Probably the correct answer! I'll try it out. Sometimes I look for more complicated solutions to simple problems.It looks like the bolt is in a T-slot, can you slide it out and try it turned round 180?

Break in done

Oil changed

Oil leak fixed (headstock top lid gasket)

DRO fuse replacement soldered and it's working

Mounted dro in likely a temporary location. I'll see how it works out.

Ways leveled (not twisted). Waiting for some 2" round bar before I can complete true up.

I also ordered one of these drill chucks. I hope it's relatively decent.

cme-tools.com

cme-tools.com

Oil changed

Oil leak fixed (headstock top lid gasket)

DRO fuse replacement soldered and it's working

Mounted dro in likely a temporary location. I'll see how it works out.

Ways leveled (not twisted). Waiting for some 2" round bar before I can complete true up.

I also ordered one of these drill chucks. I hope it's relatively decent.

MT4 Ball Bearing Keyless Drill Chuck 5/8" Integral design w. Tang #DCK | CME Tools

DESCRIPTION: "CNC Tooling" Brands---The Best Quality on The Market----Sold Many Thansands to Distributors to put on famous labels. * MT4 Morse taper 4 precision ball bearing Keyless drill chucks 1/32-5/8" (0.75-16mm). * with tang * Solid integral shank design is more compact than a combined...

Attachments

Last edited: