Hi all. Looking to show you my new lathe and also ask some questions and get some recommendations. Thank you in advance!

This lathe was imported by someone who was looking to get into gunsmithing but ended up getting a different job and selling the lathe to me. The previous owner never used it and was having trouble adapting it to single phase power.

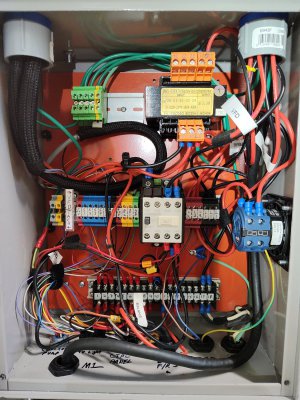

I recently finished reconfiguring much of the electrical including adding a VFD, potentiometer, and enclosure as well as new lighted jog switch, and coolant switch. I also changed all the wiring to 14 AWG instead of 18. The lathe came with a DRO and I'm redoing the mounting and repairing a blown fuse that was directly soldered to the internal board, which is why it is not shown in photos. If you're curious, I paid $4800 for it.

Please let me know what you think about the lathe, price paid, feedback on wiring and VFD, etc; positive and negative feedback welcome.

As far as questions, I need some advice on qctp+holders and a basic set of cutting tools as well as where to buy. Base of cross slide to spindle center height is ~1.75". I do have a 4 jaw, 3 jaw, and rests and centers already. I am also looking to replace the 3 phase coolant pump with a 220v single phase pump so let me know if you have a good source for that. Thank you for your feedback and recommendations!

This lathe was imported by someone who was looking to get into gunsmithing but ended up getting a different job and selling the lathe to me. The previous owner never used it and was having trouble adapting it to single phase power.

I recently finished reconfiguring much of the electrical including adding a VFD, potentiometer, and enclosure as well as new lighted jog switch, and coolant switch. I also changed all the wiring to 14 AWG instead of 18. The lathe came with a DRO and I'm redoing the mounting and repairing a blown fuse that was directly soldered to the internal board, which is why it is not shown in photos. If you're curious, I paid $4800 for it.

Please let me know what you think about the lathe, price paid, feedback on wiring and VFD, etc; positive and negative feedback welcome.

As far as questions, I need some advice on qctp+holders and a basic set of cutting tools as well as where to buy. Base of cross slide to spindle center height is ~1.75". I do have a 4 jaw, 3 jaw, and rests and centers already. I am also looking to replace the 3 phase coolant pump with a 220v single phase pump so let me know if you have a good source for that. Thank you for your feedback and recommendations!

Attachments

-

IMG_20231015_163811758.jpg283.4 KB · Views: 79

IMG_20231015_163811758.jpg283.4 KB · Views: 79 -

IMG_20231015_194532711.jpg213.2 KB · Views: 61

IMG_20231015_194532711.jpg213.2 KB · Views: 61 -

VID_20231015_194629851.mp412.4 MB

-

IMG_20231015_163859960.jpg382.5 KB · Views: 65

IMG_20231015_163859960.jpg382.5 KB · Views: 65 -

IMG_20231014_133026886.jpg242.6 KB · Views: 76

IMG_20231014_133026886.jpg242.6 KB · Views: 76 -

IMG_20231117_173227797~2.jpg423 KB · Views: 93

IMG_20231117_173227797~2.jpg423 KB · Views: 93 -

IMG_20231117_173130363~2.jpg256.1 KB · Views: 95

IMG_20231117_173130363~2.jpg256.1 KB · Views: 95 -

IMG_20231015_163451186.jpg407.7 KB · Views: 80

IMG_20231015_163451186.jpg407.7 KB · Views: 80