O

ome

Forum Guest

Register Today

Hi Guys,

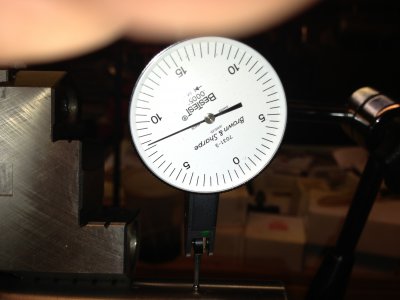

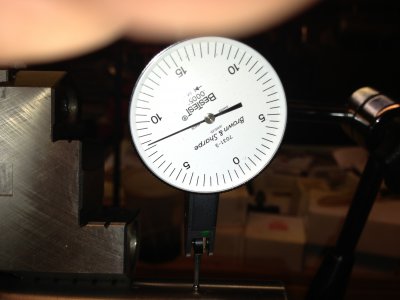

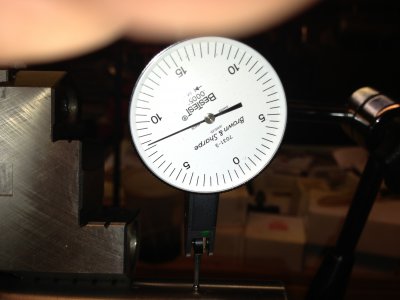

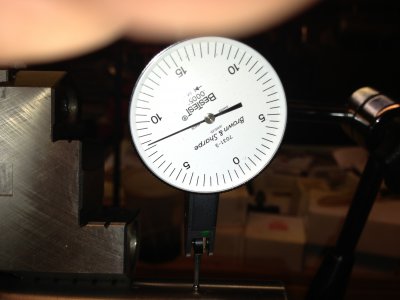

I have some pics of what the indicator came with and what i bought as extras; one mag base with dovetail female and a small mag that i am not going to use at this time..

VERY SENSITIVE, even when i turn the chuck, it moves the needle 2-4 lines

the low end is about 13 lines past the o

i put about 12-16 lines as a load and then i zeroed it out

do I have the indicator set up correctly so i can adjust this 3 jaw " adjust tru" buck chuck. How much of a load do i need for an operation like this. Here are the pics:

Thanks for any help, and I really need some guidance. jon

I have some pics of what the indicator came with and what i bought as extras; one mag base with dovetail female and a small mag that i am not going to use at this time..

VERY SENSITIVE, even when i turn the chuck, it moves the needle 2-4 lines

the low end is about 13 lines past the o

i put about 12-16 lines as a load and then i zeroed it out

do I have the indicator set up correctly so i can adjust this 3 jaw " adjust tru" buck chuck. How much of a load do i need for an operation like this. Here are the pics:

Thanks for any help, and I really need some guidance. jon