- Joined

- Jul 28, 2017

- Messages

- 2,383

The most impressive thing to me is fact that the machine is doing it so fast! BTW, I think your hypothesis is correct. The 160Kev's may be to excite some of the inner shell electrons to get more distinct x-ray lines. MaybeXRF used to sort "clean" aluminium - apparently.

I came across a video about recycling aluminium, and I admit I did not get way into the detail, but I am sure this is a direct application of XRF.

We see a (huge) set of 160 keV sources used to blast X-rays onto cut up chips of recycled aluminium on a special conveyor which uses specially controlled air blasts to knock the detected alloys into their sorting receptacles. Given the low, almost transparent nature of aluminium to X-Rays, I guess the machine might be detecting the contaminating alloy elements instead. Of course, it's way out of my league, but interesting.

The first 4 minutes relates to XRF

It also is interesting that, despite the high tech approach, they still have someone next to the conveyor belt to pluck the odd bits out.

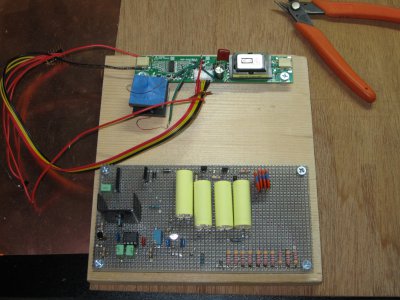

On a slightly different subject, although it hasn't rained for about 3 weeks now, it's supposed to get into the 90's the next three days. Some inside activity to escape the heat may actually include working on my HV PSU.