- Joined

- Jul 28, 2017

- Messages

- 2,383

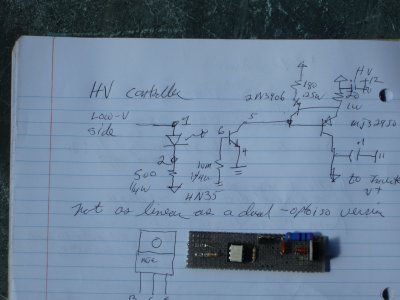

Long ago I put a commercial line filter in a box, along with a power outlet connected to the output side, to filter out line noise. I dug it out and tried it, didn't observe much of a change. But see below.Very likely, the route in is by conducted interference carried in on the 0V end of the powering arrangements. If the rest of the kit is reasonably electric field screened, then there remains the possibility of low frequency ingress by magnetic coupling, but that would be 60Hz from house wiring and appliance cables. Switcher racket from LED lamp mains step-down electronics has higher frequency blips, and finds it very easy to contaminate the house mains, the wires being quite effective transmission lines. I guess it might be time to bring out the common mode chokes and suppression measures.

It is actually possible to prevent such noise riding in on the conductors. Provided the kit has reasonable electric field screening, you can expect to be able to eliminate the switcher waveform contamination, and let the lamps keep making a racket.

Even getting a scope to confirm the noise on the trace is real can be a challenge. I have found I often cannot just clip the ground of the probe to a 0V, and the common way of allowing the circuit 0V to find it's way onto frame metal would likely defeat attempts to get the signal clean. In my stuff, the usual effect of such grounding does, to a reasonable degree, reduce the coupled trace noise wobbles to a certain low(ish) level), which then resists attempts to clean it further until the circuity is isolated from the frame. Sometimes you can see "PSU switcher noise", and discover it is just a measurement artifact that goes away when dual differential probes are used.

TFT display, being so intimately connected to measurement circuits, might perhaps need to be separately cleaned up. I think I would be unhappy with as much as as 10mV, but I do accept that the 500uV to 1mV level is a darn hard thing to achieve.

Turning the scope probe into an antenna loop (by connecting the ground clip to the probe) revealed lots of EMI coming from my scope. It's worse near the back, probably from the scope's switching power supply. Evil things they can be. It seems likely that the scope is a major source of the noise I'm seeing -- it was on the filtered side of my little line filter setup.

I'll have to try my little battery-powered DSO. It could still contribute some noise from its TFT but hopefully no switching PSU is in it.