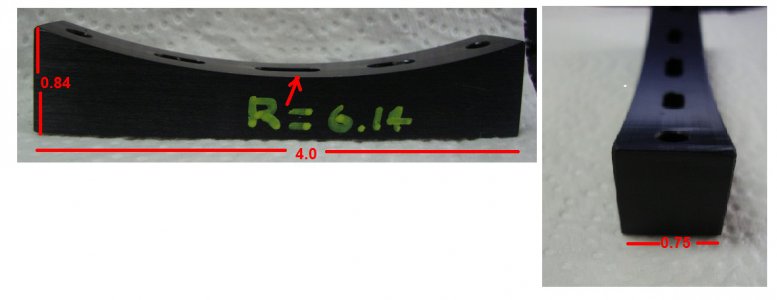

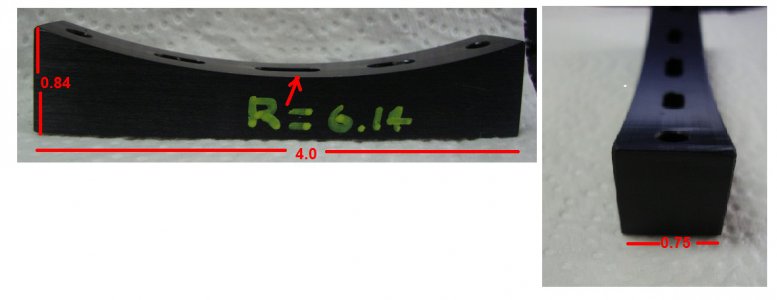

I have a very basic understanding of how to use a mill and lathe. I have milled parts with my Go704 and turned pieces on my ENCO 9" lathe. I want to duplicate this part and end up wit a good fit and finish. I'm not sure if I could use the lathe, but it seems that the mill would work. My mill is not CNC. I have an assortment of end mills, gauges and accessories, including a 6 inch rotary table. Could you pleas offer some suggestions for duplicating this part. Note, the location of the holes will be determined later. I have 3/4'' aluminum stock on hand. The most important specification is the radius because this part attaches to a cylinder with the same radius. Thanks in advance! Frank