- Joined

- Aug 6, 2015

- Messages

- 3,908

I'm tired of cutting machining blanks with a hacksaw. I prefer a bench top band saw, since I don't have much space available for a floor model bandsaw. Most material I cut is less than 2" steel or 3" aluminum. Would the vertical cutting ability of a floor model band saw be useful? Any recommendations less than $500?

Sharing with the OP in case this works for him...

After reading this thread and looking to converting what I have to work both horizontally and vertically... I went looking for something similar already made... I ended up buying a WEN 3975T 4-7/8-inch x 5-inch Metal-Cutting Benchtop Band Saw - came out to less than 300.00. It was more than what a 4x6 from Harbor Freight would have cost, but I just do not have the space right now to accommodate that one...

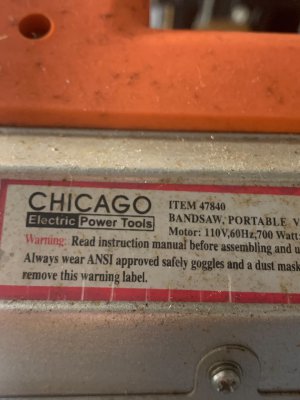

When I started looking at the portable that I have, that one is not the one that a lot of folks transform into vertical and horizontal... looks to be a cheaper, earlier model... so no provision to place it vertically with a plate to act as a table... I would need to drill, tap make a shim, etc. To make it work in the vertical position. Not something I want to deal with right away...

For the next projects that I want to tackle, I just need a horizontal bandsaw. And with this new one, I can later make a table for it to use it in a vertical setup. Something like this guy did: