-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

VN My Vn & Parts Drawings And Manual

- Thread starter HMF

- Start date

- Joined

- Dec 6, 2012

- Messages

- 2,677

..... this also means I can run the table (part, vise, etc.) into the tool while it is not running. But such is the case with the Bridgeport setup as well, except the quill feed. Table feeds are separate and run regardless of spindle powered on or off.

Are the installation of limit switches an option?

But, then we'd need to take the time to set the limit switches....

Kind of like putting the guard down on the bench grinder.

Daryl

MN

- Joined

- Dec 6, 2012

- Messages

- 2,677

There does not appear to be a "standard" wiring diagram for the smaller Van Norman mills. In fact, I seem to recall that you could buy them un-wired and do it yourself. Every one that I've seen has been different.

All of the Van Norman machines that I know of were wired with a rotary switch of some sort that controls what runs when the start button is pushed. You can select spindle plus optional feed and/or coolant. I haven't seen one, at least in the No. 12 size, that was wired so that the feed would run without the spindle. The feeds is pretty slow an a No. 12 and there is no rapid, so using it for table positioning isn't much use; much easier to just grab the handle and crank to where you want to be.

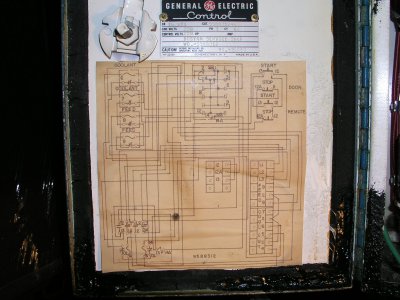

Cal

Cal attached are the remnants of the diagram inside the door of my VN6. It shows options for powerfeeds and coolant which were never available for the VN6. Additionally, there is huge space in the box. When I got the 1140rpm 3phase I returned all the electrical to the original box. Fortunately, it remained after the 1phase 1725rpm was installed.

Daryl

MN

- Joined

- Jan 22, 2011

- Messages

- 8,031

Daryl, my only uses for limit switches are for unmanned cuts, and overtravel limits to avoid damage. Not to keep you from running over stuff. That's the machinist's job

- Joined

- Dec 6, 2012

- Messages

- 2,677

"limit switches are for unmanned cuts, and overtravel limits to avoid damage. Not to keep you from running over stuff."

Agreed.

And yet we add all kinds of guards and idiot lights because common sense is uncommon.

Daryl

MN

Agreed.

And yet we add all kinds of guards and idiot lights because common sense is uncommon.

Daryl

MN

- Joined

- Sep 3, 2011

- Messages

- 478

Daryl,

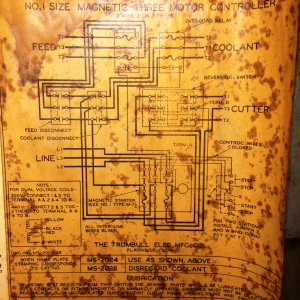

Thanks for the wiring diagram. That appears to be a generic controller. It may have been added to the machine after it left the factory, perhaps years after.

Limit switches are an option. You use as many normally closed (NC) switches as you like, connected in series with the coil of a relay that controls power to the feed motor. When any one of the switches is opened, the circuit is broken and the feed motor stops. It's common to have both soft and hard limit switches: The hard limit switches often shut down the entire machine and are permanently installed to protect the machine from damage when an axis over travels. The soft limits switches can be set up to be moved by the user to stop and axis at a desired place, much like the mechanical feed disconnect on the VN12 and up.

Cal

Thanks for the wiring diagram. That appears to be a generic controller. It may have been added to the machine after it left the factory, perhaps years after.

Limit switches are an option. You use as many normally closed (NC) switches as you like, connected in series with the coil of a relay that controls power to the feed motor. When any one of the switches is opened, the circuit is broken and the feed motor stops. It's common to have both soft and hard limit switches: The hard limit switches often shut down the entire machine and are permanently installed to protect the machine from damage when an axis over travels. The soft limits switches can be set up to be moved by the user to stop and axis at a desired place, much like the mechanical feed disconnect on the VN12 and up.

Cal

- Joined

- Jan 22, 2011

- Messages

- 8,031

Daryl, I meant by unmanned cuts long cuts that are safe enough to turn my back on and do something else productive and let the feed kick out when the cut was done. In those cases it's not like you are moving towards a shoulder or anything. I wouldn't likely use a stop for that either. Just cuts that clear the end of the stock.

- Joined

- Jun 6, 2015

- Messages

- 283

I have an extra tail stock, I'll have to look but I think its for the 7 1/2". Message me for more info.

Jason

Jason