- Joined

- Apr 20, 2013

- Messages

- 210

Huge amount of work accomplished today on this floor!! Finished grading, compacted base, 10mil poly sheeting down and taped, 1.5" extruded poly styrene foam sheets down and taped, concrete mesh down and tied, 2560 sq feet of 1/2" pex ran in nine loops, and about 2000 wire ties twisted!! Plastic step2 garden carts saved me tonight!!

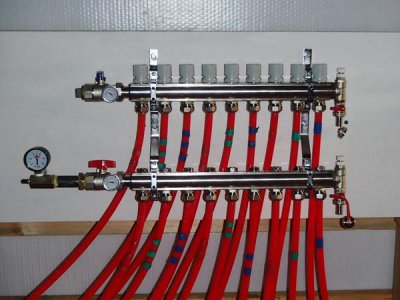

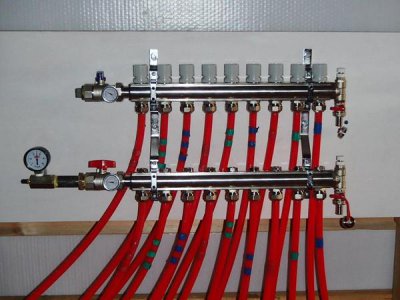

Next up, pex manifold install and a 24 hour pressure test and waiting for the ground to dry out so we can get some cement trucks in!! Floor poured SOON!

Next up, pex manifold install and a 24 hour pressure test and waiting for the ground to dry out so we can get some cement trucks in!! Floor poured SOON!