- Joined

- Mar 27, 2022

- Messages

- 417

The lathe has made it home safely!

Luckily it only had to go 7 miles. It did involve some bumpy country roads and driving slow. As I am looking through this I have some questions.

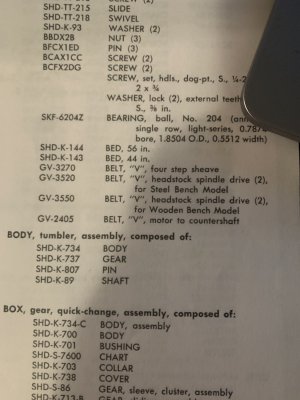

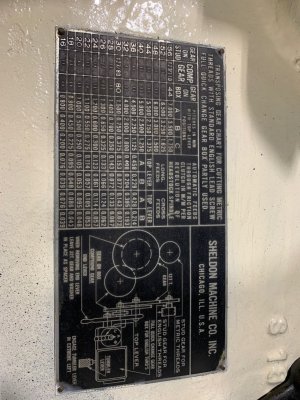

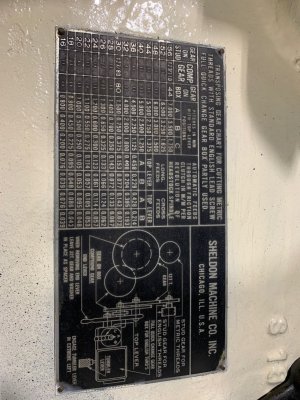

First is the change gears, from what I can guess I think these are just for metric threading? If so I dont have a 127 gear or an 80 gear. What do you think the other banjo's are for? Also can anyone confirm what the standard inch cutting gear arrangement is supposed to be?

\

\

Also what in the world is this gear??

Second, what is the big round pieces on the collet set, are they just spindle protectors?

What are these mag chuck looking things? They arent magnetic. I have two of them.

I am pretty sure this lathe is wired in 220 as 2 and 3 are bonded together, does that seem correct?

I am going to some new belts mainly the spindle belts as they are delaminating. Are matched belts a thing nowadays or is your off the shelf belts close enough? Also any idea what size I need?

Current final question, is there a way to adjust backlash in the crossfeed screw/nut?

Thanks in advance!

Luckily it only had to go 7 miles. It did involve some bumpy country roads and driving slow. As I am looking through this I have some questions.

First is the change gears, from what I can guess I think these are just for metric threading? If so I dont have a 127 gear or an 80 gear. What do you think the other banjo's are for? Also can anyone confirm what the standard inch cutting gear arrangement is supposed to be?

\

\

Also what in the world is this gear??

Second, what is the big round pieces on the collet set, are they just spindle protectors?

What are these mag chuck looking things? They arent magnetic. I have two of them.

I am pretty sure this lathe is wired in 220 as 2 and 3 are bonded together, does that seem correct?

I am going to some new belts mainly the spindle belts as they are delaminating. Are matched belts a thing nowadays or is your off the shelf belts close enough? Also any idea what size I need?

Current final question, is there a way to adjust backlash in the crossfeed screw/nut?

Thanks in advance!