- Joined

- Sep 8, 2019

- Messages

- 4,392

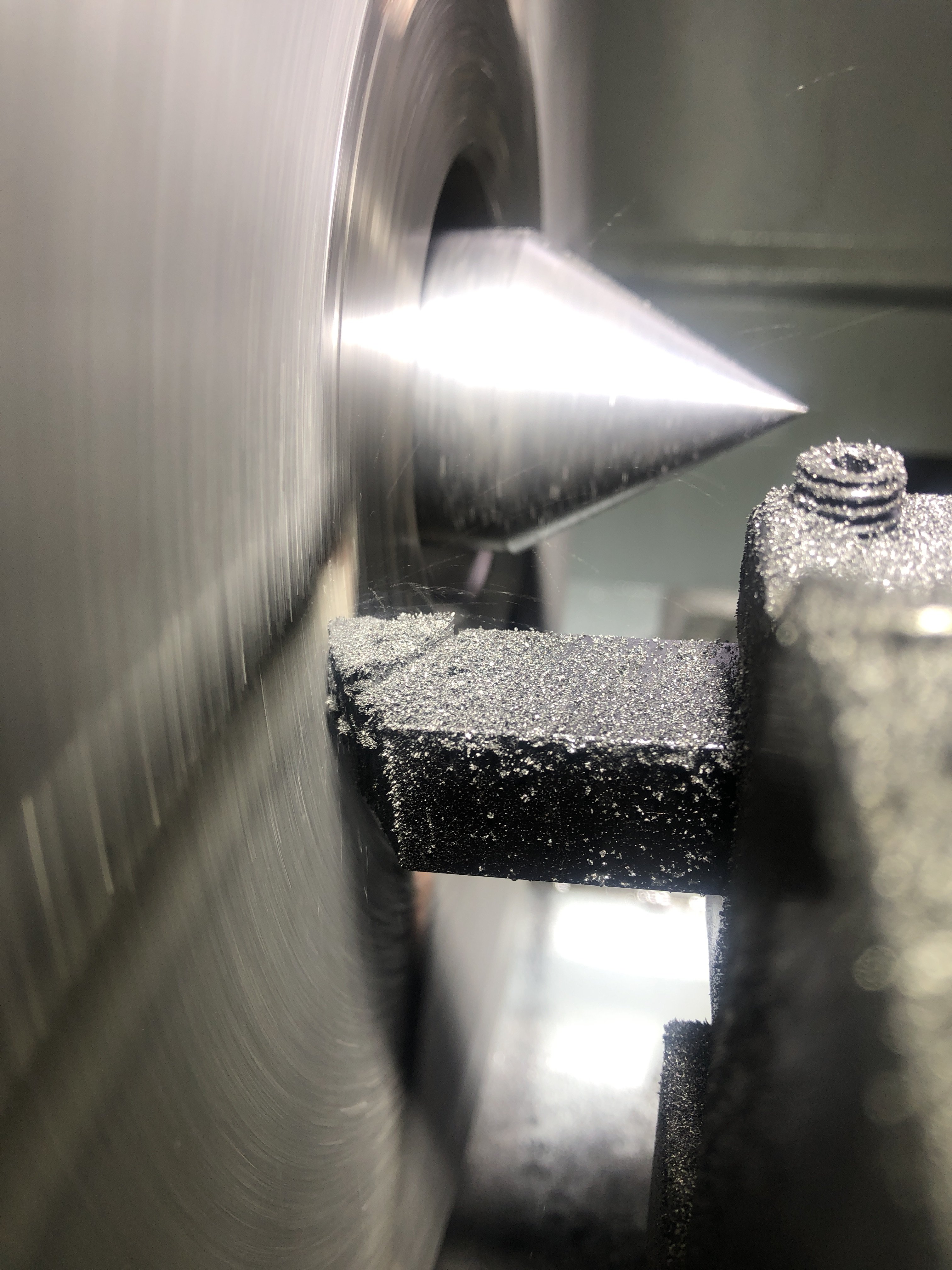

This is my first experience with cast iron. I know to clean the grit & cut it dry.

.010” DOC, 70 RPM, .005” feed, A6 carbide.

.010” DOC, 70 RPM, .005” feed, A6 carbide.