- Joined

- Sep 8, 2019

- Messages

- 4,392

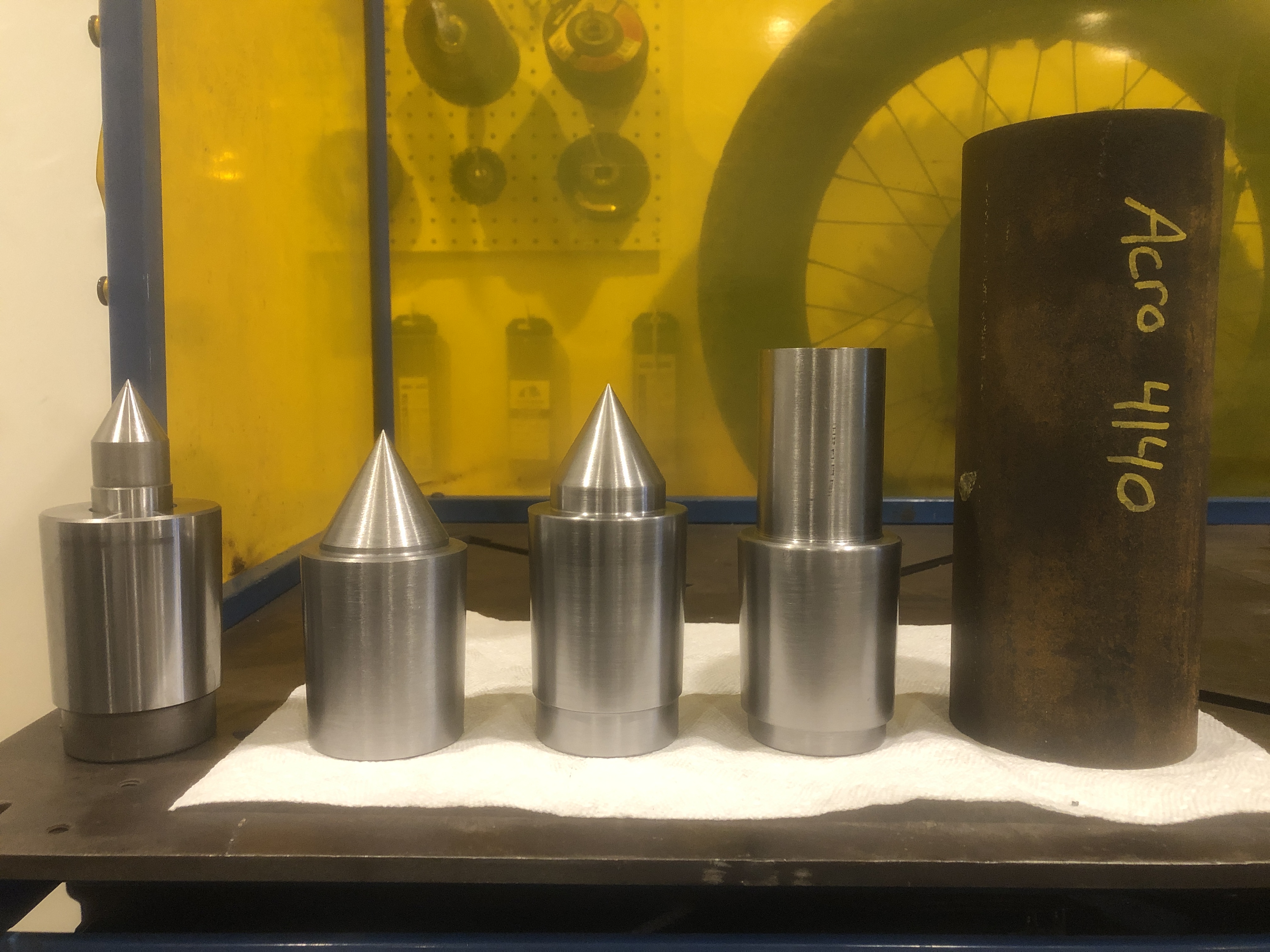

So here is what I have so far. From left, stock PM adapter sleeve with MT4 dead center, 1018 steel first try, 1045 steel from today, another 1045 from last week (I still need to cut the 60° tip), and 4” 4140 prehard round stock for the last one.

I’m going to force myself to try my taper attachment for the chromoly one. I have been afraid to use the taper attachment; I was afraid that I won’t be able to re-engage the cross slide after disengaging it to use the taper attachment.

I’m going to force myself to try my taper attachment for the chromoly one. I have been afraid to use the taper attachment; I was afraid that I won’t be able to re-engage the cross slide after disengaging it to use the taper attachment.