Hi All

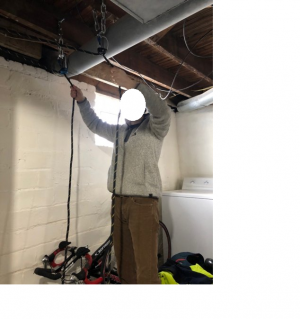

After this freak April snow storm passes I am going to attempt moving my new lathe down to my basement machine shop.

What do you all think of my approach?

The lathe is currently bolted into a pallet like structure. (I removed the real pallet.)

My ramp is four 2" x 6" x 8' braced lumber with a 1/2" sheet of plywood screwed in on top.

The ramp is just leaning into rock wall.

I plan to hook up my manual 1 ton worm gear winch to my trucks hitch and then use the winch to slowly lower onto plywood at bottom.

Obviously the tail end of the lathe will be sticking out a bunch before it starts to angle down.

Any thoughts on bad things that may arise?

As always, any and all help is greatly appreciated.

After this freak April snow storm passes I am going to attempt moving my new lathe down to my basement machine shop.

What do you all think of my approach?

The lathe is currently bolted into a pallet like structure. (I removed the real pallet.)

My ramp is four 2" x 6" x 8' braced lumber with a 1/2" sheet of plywood screwed in on top.

The ramp is just leaning into rock wall.

I plan to hook up my manual 1 ton worm gear winch to my trucks hitch and then use the winch to slowly lower onto plywood at bottom.

Obviously the tail end of the lathe will be sticking out a bunch before it starts to angle down.

Any thoughts on bad things that may arise?

As always, any and all help is greatly appreciated.