- Joined

- Sep 20, 2020

- Messages

- 347

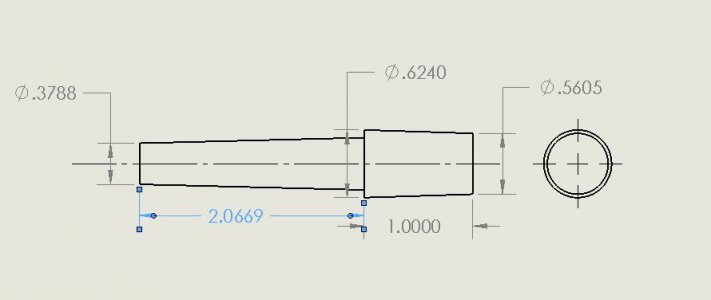

i want to try and cut a taper because I have a second operation hardinge lathe. I have to set the taper and I want to try it.Do you have a tail stock chuck? Unless you want to play with the taper, you can make the shank cylindrical, and use the chuck.

Maybe consider adding a through hole so you can punch out the ram and bushing if you ever want to remove them.

I will make the taper long with extra material for more range. I don't have a 3/8 bottoming tap though. if I did I would thread it.I would suggest a shorter stickout of the tap guide. When full compressed, the point should just engage the tap wrench. One of the shortcomings of commercial tap guides is the short travel. I would like to see .75" as a minimum. Rather than a press fit or set screws for your retainer, consider threading the retainer for easy removal for repair or servicing.

If you are startng with an existing taper, I would suggest using a MT1-JT33 adapter. It will give you an additional 1" of material to work with. If you are making your own taper, Just leave additional material on the taper.

View attachment 357837

.

it could have a morse taper 2. my wood lathe has a morse taper 2 and the ram is smaller than that on my metal lathe.I like the idea of using the taper-area for this, I know any lathe with an MT1 likely doesn't have the bed length to spare for a drill chuck!

For serviceability, I might suggest making the bushing thread-in instead of pressed in. That would give you the ability to pull it apart easy enough. Then just use a pair of holes for a spanner wrench or something (or, just have it protrude a 1/4" for flats).

luckily I know more about machining and like machining than video games. only get grounded from wood and metal working if I get my phone and iPad taken away. they can only block it on my phoneI'm guessing you missed some homework? Next will be parental block on this web site. Boundaries, limitations, and consequences

.

.