- Joined

- Sep 8, 2019

- Messages

- 4,392

Out of nowhere one of my coworkers asked to buy one of my eBikes, & it is just enough money to buy a Millermatic 252 that I will use for FCAW.

I have had a Millermatic 252 for about 3 years that is set up for MIG. I have always used .035” wire & C25 shielding gas. It is a nice machine to weld with.

I could switch out the rollers & wire to run .035” flux core on the Millermatic 252 that I have now, but I like to have my machines ready to plug in and go.

I have only run about 6” of flux core bead in my entire life & I have always wanted to get into it. I don’t know if I will use .035” or .045”, but I am leaning toward .045” because that is a really common size.

Anybody here ever do any FCAW?

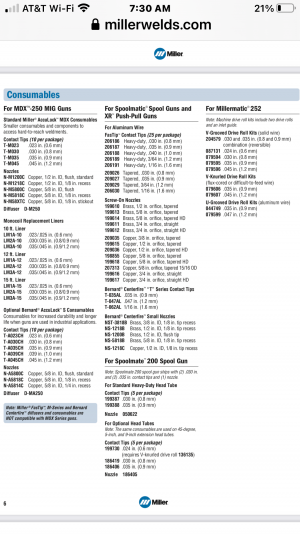

Miller ships these machines set up for .035” wire diameter with rollers for MIG wire. I will have to buy FCAW rollers & put those in. If I want to run .045”, I am pretty sure that I will need to put in the correct sized liner for that.

I have had a Millermatic 252 for about 3 years that is set up for MIG. I have always used .035” wire & C25 shielding gas. It is a nice machine to weld with.

I could switch out the rollers & wire to run .035” flux core on the Millermatic 252 that I have now, but I like to have my machines ready to plug in and go.

I have only run about 6” of flux core bead in my entire life & I have always wanted to get into it. I don’t know if I will use .035” or .045”, but I am leaning toward .045” because that is a really common size.

Anybody here ever do any FCAW?

Miller ships these machines set up for .035” wire diameter with rollers for MIG wire. I will have to buy FCAW rollers & put those in. If I want to run .045”, I am pretty sure that I will need to put in the correct sized liner for that.