- Joined

- May 14, 2013

- Messages

- 237

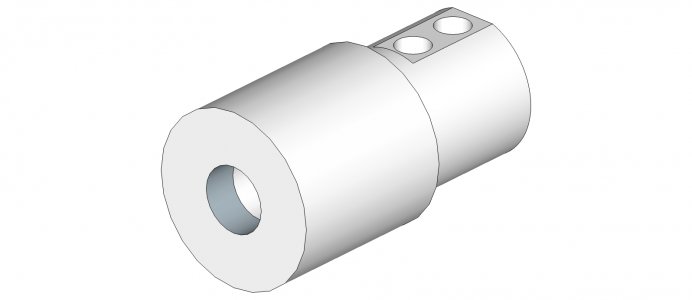

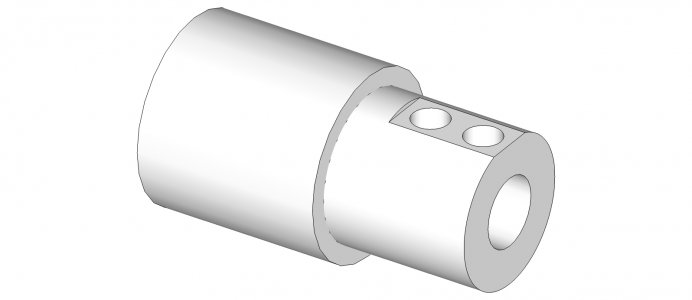

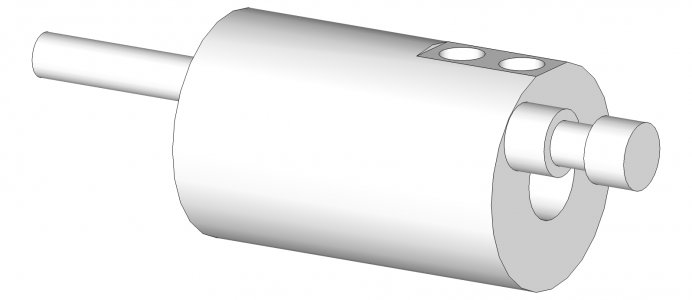

Does anyone have a PTG(TM) micrometer reamer stop they would be willing to share some dimensions with me? I am undertaking my first re barrel / chamber job and can use all the help I can get. Thanks in advance.

How do you set headspace with the DRO?I have this tool and never used it. When I get ready to chamber I just have at it with a floating reamer holder in the tailstock and use the DRO to set headspace. As quick and as accurate as needed. I build benchrest rifles that are very competitive. I bought this device because I was intrigued as to how accurate you can set headspace. I might play with it some day.

I understand that this works for you. That is great. I am confused as to where you start your measurement from, i.e. when do you set your dro to zero?I have a DRO on the tailstock quill.

And an indicator on the lathe bed so the carriage always returns to the exact same position. All chambering is done through the headstock with a spider on outboard end

View attachment 347729