Yep....I noticed that too. I have always wondered what value those were. Seems to me the damage would already be done by the time it slipped. I think my machine has one also...can't remember if it's on this one or one of the previous machines. I'll have to look at it tomorrow.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Logan Model 1875 Info

- Thread starter HiCap239

- Start date

A 6" vise is overkill for a RF45 style mill. A 4" is more appropiate for that size mill & IMO 5" max. I have a 5" GMT vise on my PM45 & it's slightly too big. Not enough Y axis travel to make use of the 5" full capacity. Better to save your money rather than getting something too big & most importantly the weight. I take my vise of the table quite often, a 6" is still light enough for me to be carried by hand but I'm glad I have a 5". I also have a 4" vise as well. I prefer the 5" though.

But those GMT 6" Premium vises are pretty nice. I'd love to have one but don't need one on my current mill. But if you plan on upgrading to a full size knee mill in the future than the 6" will be perfect.

Here's what the 5" looks like on my mill.

I couldn't even complete this cut without my bellows & DRO scale getting in the way. Not enough Y travel & the 5" vise is not even maxed out.

Here's what a 6" vise looks like on another PM45 (gt40's)

View attachment 253544

But those GMT 6" Premium vises are pretty nice. I'd love to have one but don't need one on my current mill. But if you plan on upgrading to a full size knee mill in the future than the 6" will be perfect.

Here's what the 5" looks like on my mill.

I couldn't even complete this cut without my bellows & DRO scale getting in the way. Not enough Y travel & the 5" vise is not even maxed out.

Here's what a 6" vise looks like on another PM45 (gt40's)

View attachment 253544

- Joined

- Dec 14, 2013

- Messages

- 167

This thread has a drawing of the key posted by Artemetra on the first post. Should be of some help. You will also need a small spring.

http://www.hobby-machinist.com/threads/logan-820-latch-key-repair-and-question.23897/

http://www.hobby-machinist.com/threads/logan-820-latch-key-repair-and-question.23897/

Last edited:

Thanks for the link, Looks like I know what the first project for the lathe is going to be, along with a cleaning. Hopefully there will be no surprises with anything later on. But if there is I know that you guys are a wealth of knowledge. Thanks again for the info!

- Joined

- Dec 25, 2011

- Messages

- 10,513

Yep....I noticed that too. I have always wondered what value those were. Seems to me the damage would already be done by the time it slipped. I think my machine has one also...can't remember if it's on this one or one of the previous machines. I'll have to look at it tomorrow.

The purpose of a slip clutch on the lead screw is to protect the drive train if for example you run the carriage into something that does not immediately stall the spindle. The drive train can continue to run while not turning the lead screw, until the operator manages to stop the motor. It would also protect the drive train if for example you engaged the carriage drive with the carriage lock locked. Obviously, if you run the carriage or something on it directly into something connected to the spindle (like a chuck jaw), that may stall the spindle, and/or damage something else. The late QCGB equipped Atlas/Clausing 12" machines also have a slip clutch for this purpose. It is on the output from the GB to the lead screw.

I read through the description of the clutch. Apparently it's a lot more useful than I suspected. I was picturing someone running the compound into the chuck. (Which if the lathes I've had are any indication, happens quite often). I would still be skeptical about it protecting the qc box. I checked my lathe and found that it is in fact outfitted with one. I should have thought to look at the compound also. I've never owned one that didn't have damage on it. My memory isn't that good but I think I had to replace a tumbler gear on this machine when I got it. I could be confusing it with a different machine. In any event I've never had the opportunity to put the slip clutch to the test.

M

Mister Ed

Forum Guest

Register Today

OK, where are the pics of this machine??

Oops ... not picking up until tomorrow.

Oops ... not picking up until tomorrow.

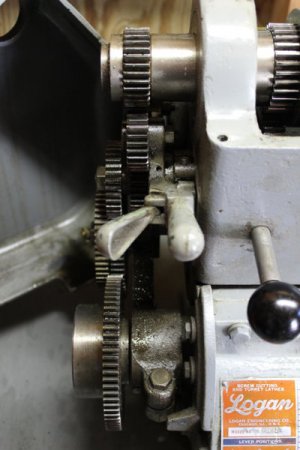

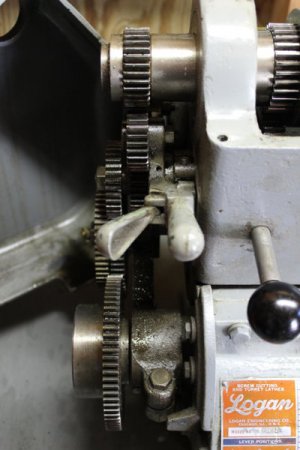

OK, I got everything taken care of today, those things are heavier than I thought. Ended up renting a 3' x 5' Home Depot trailer for $15.64 for 4 hours. I have is temporarily on furniture dolly's until I decide on its final placement. I have right around $900 in it. Did I do ok at $900? I thought it was worth it because of the Starrett and Brown & Sharp measureing instruments. This includes the Starrett depth gauges, and the boxed Starrett set along with a Brown & Sharp dial indicator. The knurling tool is pretty neat also. I have never seen one that had 4 different patterns in one package. But then again I am fairly new to this. There were a lot of small assorted lathe bits, some new that I did not include in the photo, because well they are boring, Lol. I did give it a good wipe down and ended up rechecking the ways with a set of new parallel bars I just got. The Ways are actually in a lot (dare I say Way) better shape than I had originally thought. Not too sure about that chuck, it seems small. It has a single key slot, not 3 like my ENCO 9 x 20. I noticed the chuck key size if 1/4"? I think I will be shopping around for a new slightly larger chuck in the foreseeable future.It says Kalamazoo IND on it which makes me think it is of decent quality, does anyone know anything about this chuck? I looked at the Shifter Rack Assembly when I got it home also. There is a shot of that here also. Looks like the Latch itself is broken. At least the pin is in the shifter rack and there is part of the Latch itself. This is great news, as it gives me a starting point for the template. Enjoy the pics and thanks everyone for all the help and sharing your knowledge and information with me.OK, where are the pics of this machine??

Oops ... not picking up until tomorrow.

M

Mister Ed

Forum Guest

Register Today

Very nice, it looks like you did pretty well.

- Joined

- Apr 30, 2015

- Messages

- 11,329

Looks good to me, I wouldn't mind having a Logan at all  Good deal

Good deal

Mark S.

Mark S.