Brace yourselves, a wall of text is inbound

Wow what happened to the board? How was the milling going to the point? As I recall you were going to do a wide plate, is this block just practice or isit for something?Mark

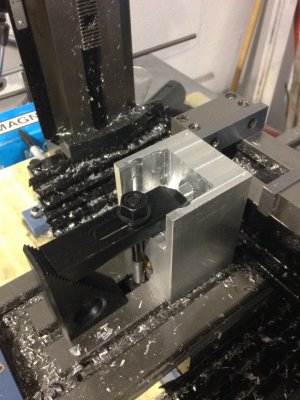

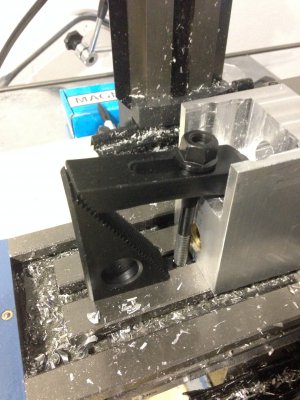

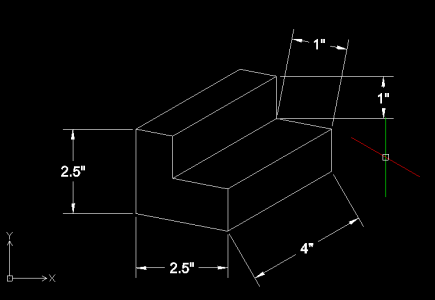

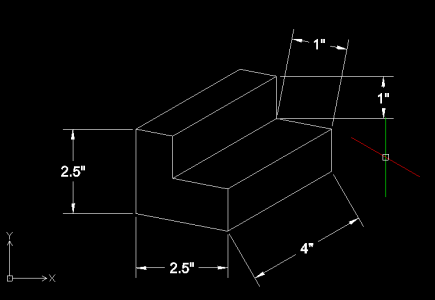

Same project, the block I was working on will have a lug on the bottom that will rest in the slot.

Had I known you were going to use that large a cutter, for that long a period, I would have suggested you look at a PM 932 or something similar.

I don't even use a 5/8" end mill in my PM25. The LMS isn't going to last very long at that work load. It simply isn't built to handle it for a prolonged period.

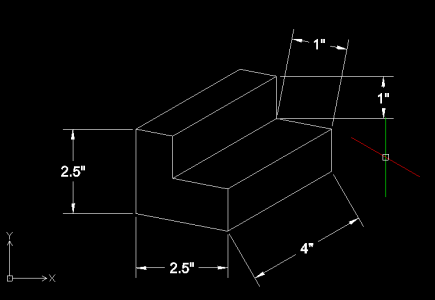

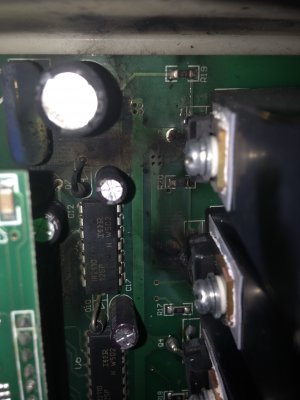

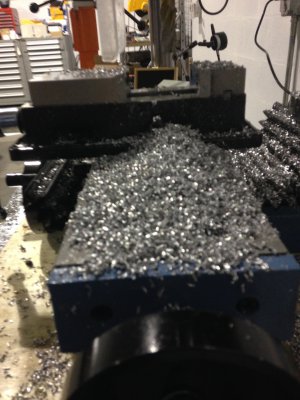

I got the new board today and have the mill back up and running. To avoid the overload issue in the future I'm going to be installing an exhaust fan in the main control box and am looking at ways I can alter my design to require less intense machining. Rather than the bunch of U slots and enclosed areas which I would need to painstakingly chip away at, I reworked the parts to only require L shaped notches that are open on the top and side and go the full length of the workpiece (see below). Working in from the side will avoid the heavy load caused by prolonged, full engagement cuts and should really lower the stress on the electronics.

That being said, I'm wondering if I can't do better still using a slitting saw to remove the corner with two perpendicular cuts that run the length of the bar. Do you all think the machine can handle it? Not having to turn the whole volume into chips would certainly be less work but it might require more power than I have available.

I was thinking about buying

this slitting saw and putting it on

this arbor so that I could cut out the the notch and have a 1"x1" bar left over instead of a giant pile of chips. I'd take it slow and not try and do it in a single pass obviously but I wonder if it might not still be more than the mill can handle.

I really appreciate all the advice y'all have given me. Like I said in the OP, this is way deeper than anything I've tried before.