- Joined

- Sep 7, 2019

- Messages

- 674

Just did some more grinding.

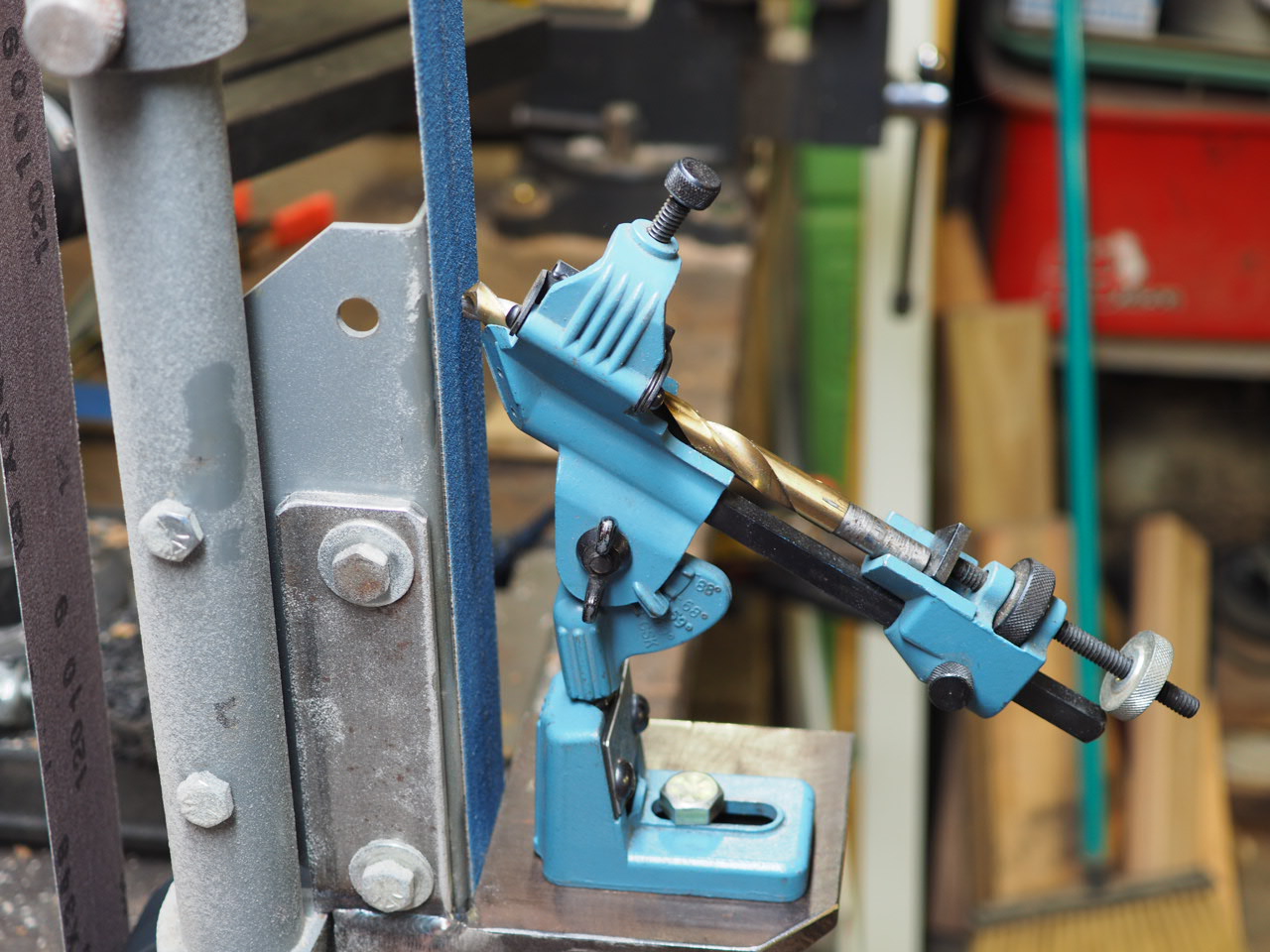

Here's a pic of how my jig mounts. When I mention clockwise (CW) or counter clockwise (CCW) it's from my perspective standing behind the jig. Thus a CW rotation rolls the top part of the bit facing the ceiling towards my right hand side. Just to clarify.

I did an experiment by grinding a few similar size drills in various orientations. One with the cutting edge straight vertical, or plumb if you like. One with the cutting edge rolled CW and one with the cutting edge rolled CCW. Results follow!

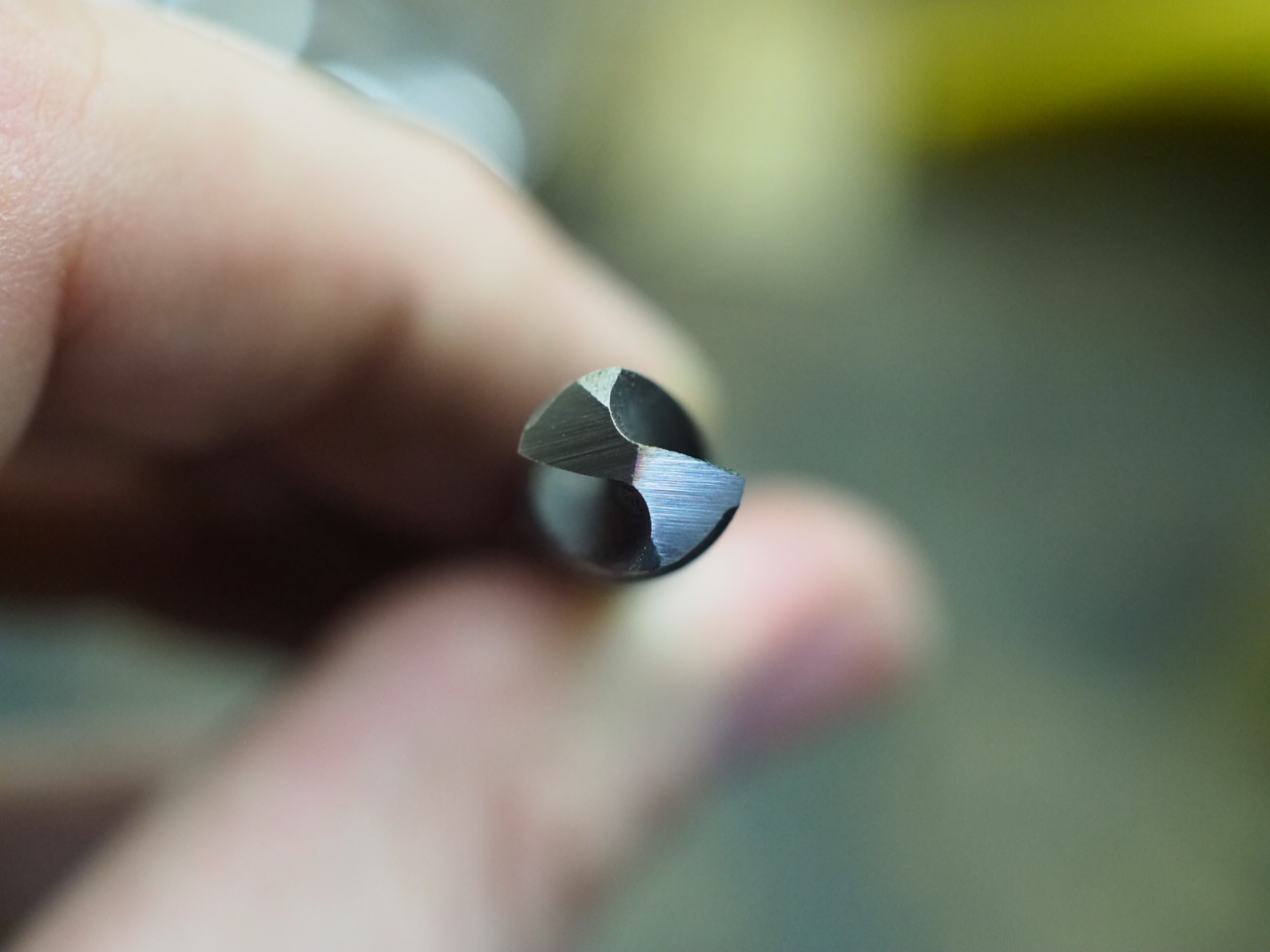

First up was the bit rolled CW. The cutting edge lines up with the red mark, roughly.

Here's the relief from that same bit. It's a little steep.

And a shot of the chisel from that same bit. The angle's not quite right.

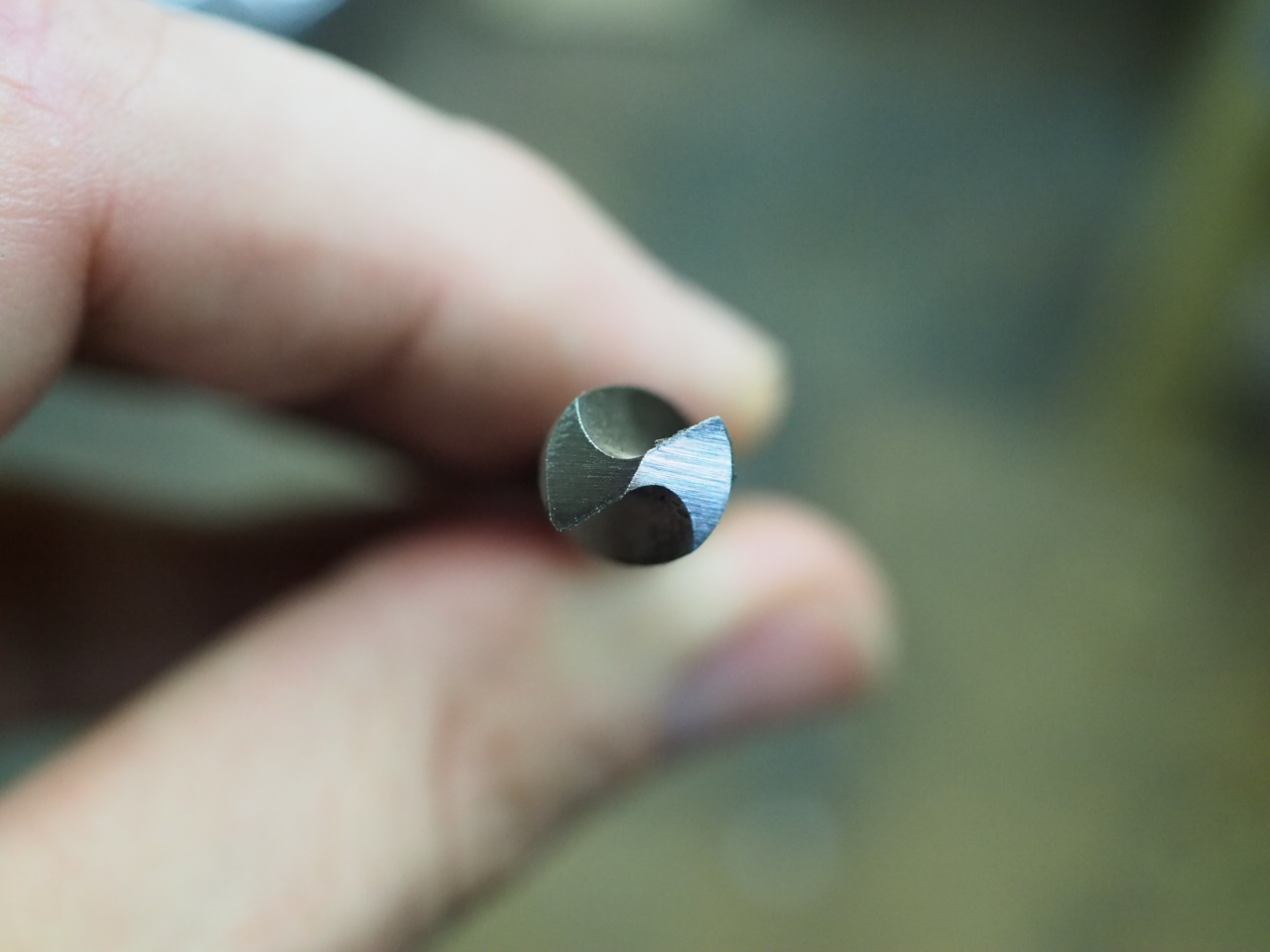

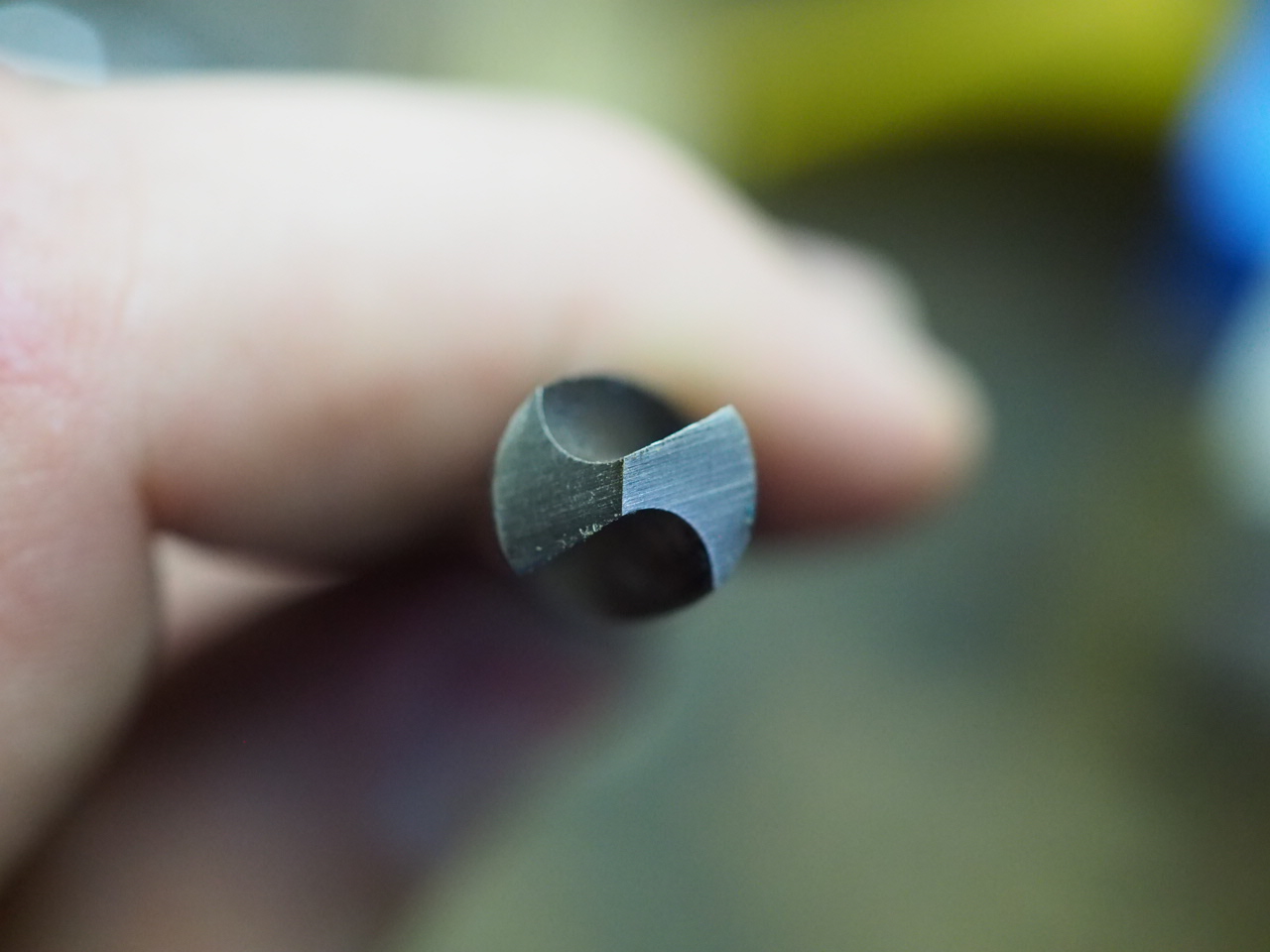

Next was the drill bit with the cutting edge vertical or plumb.

Here's the relief from that same bit. Looks pretty good.

And the chisel from that same bit. The angle looks right to me.

And also a comparison of that same bit next to a factory grind. Factory is on the right side. The angles are pretty close to the same.

Finally is the bit with the cutting edge rotated CCW from vertical. The cutting edge lines up with the black mark.

Here's the relief from that bit. It's completely negative and unusable.

And the chisel tip from that bit is going the wrong way.

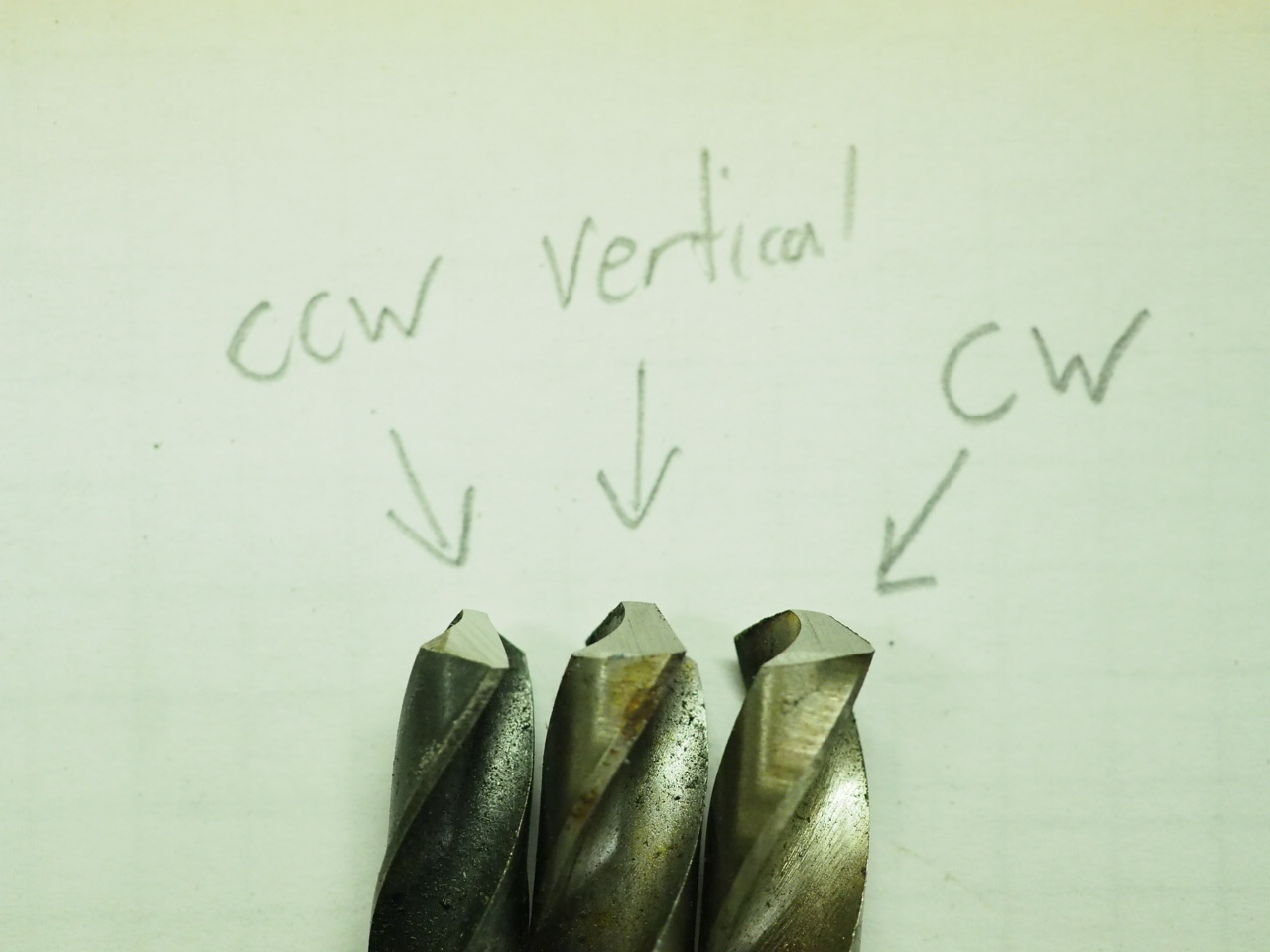

Lastly I took a shot of all three bits side by side to compare relief angles.

I kind of like the relief on the CW one but the chisel is not very good on that one. To me overall the vertical on looks the best. Maybe just a few degrees CW off of vertical would be where I settle.

Next I'll try a few different setting from vertical to maybe 10 or 15 degrees CW and see what happens.

Here's a pic of how my jig mounts. When I mention clockwise (CW) or counter clockwise (CCW) it's from my perspective standing behind the jig. Thus a CW rotation rolls the top part of the bit facing the ceiling towards my right hand side. Just to clarify.

I did an experiment by grinding a few similar size drills in various orientations. One with the cutting edge straight vertical, or plumb if you like. One with the cutting edge rolled CW and one with the cutting edge rolled CCW. Results follow!

First up was the bit rolled CW. The cutting edge lines up with the red mark, roughly.

Here's the relief from that same bit. It's a little steep.

And a shot of the chisel from that same bit. The angle's not quite right.

Next was the drill bit with the cutting edge vertical or plumb.

Here's the relief from that same bit. Looks pretty good.

And the chisel from that same bit. The angle looks right to me.

And also a comparison of that same bit next to a factory grind. Factory is on the right side. The angles are pretty close to the same.

Finally is the bit with the cutting edge rotated CCW from vertical. The cutting edge lines up with the black mark.

Here's the relief from that bit. It's completely negative and unusable.

And the chisel tip from that bit is going the wrong way.

Lastly I took a shot of all three bits side by side to compare relief angles.

I kind of like the relief on the CW one but the chisel is not very good on that one. To me overall the vertical on looks the best. Maybe just a few degrees CW off of vertical would be where I settle.

Next I'll try a few different setting from vertical to maybe 10 or 15 degrees CW and see what happens.

Pretty siked to get one. They look like this for those that don't know. What is nice is that the company is still in business to get parts.

Pretty siked to get one. They look like this for those that don't know. What is nice is that the company is still in business to get parts.