I am going to try something I have never done before but I have seen other builders talk about it and have seen the results so why not give it a try.

I have always made my rod bushings for the crankshaft end from round stock and sawed them in half or close to in half as I could so they would fit around the crank journals. This leaves things a little less than desired where the half's come together and the halfs are not always the same size.

So here goes.

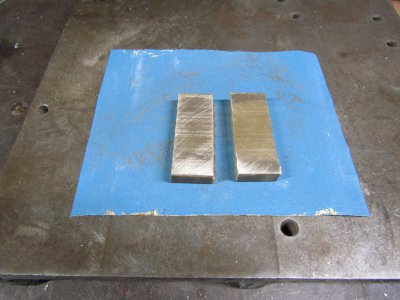

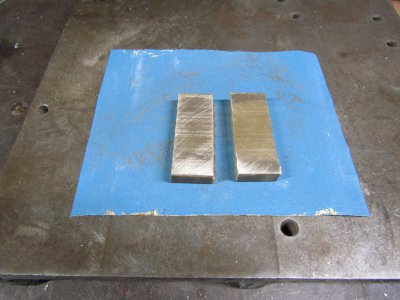

I started with a couple of pieces of hard brass 0.312 in thickness and about the same size.

Over to the mill to square them up and make them the same size in height and width. This gives me a 0.625 square piece about 2" long with a split going down the center.

I then sanded the mating sides and super glued them together.

After 5 minutes it was over to the 4 jaw and I dialed them in to run as true as possible.

I turned the outside diameter round and it ended up about 0.610 which was fine.

Using a parting tool I cut the flanges for the depth and width of the connecting rod and started on the center hole.

I was afraid the two halfs would split apart when I started drilling the center hole for the rod journal but that didn't happen. Things went remarkably well with no problems.

Back to the parting tool to finish cutting the bushings off. I made two bushings at a time in case this didn't work I wouldn't waste too much material on my first try.

Here are the first two right off the lathe.

And installed in the connecting rods.

The first two bushings took me over 3 hours to make but the second two took only about 45 minutes.

This is a much neater and a more accurate way of making rod bushings so here they are all installed..

Thanks for looking

Ray