The bore is 20mm = .787in and the inch size mandrels I was looking at (first attachment) would not work, I'd have to reduce the bore to .75in.

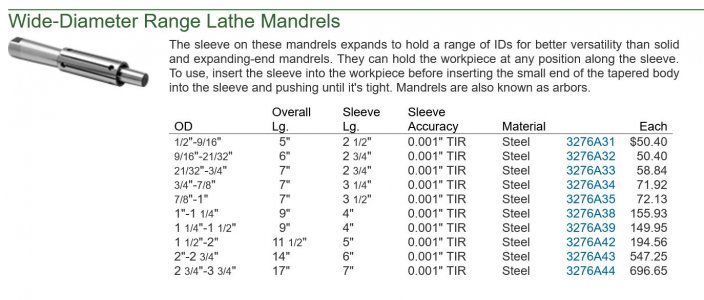

I now see more expensive wide-range mandrels (second attachment) that ought to work.

I now see more expensive wide-range mandrels (second attachment) that ought to work.