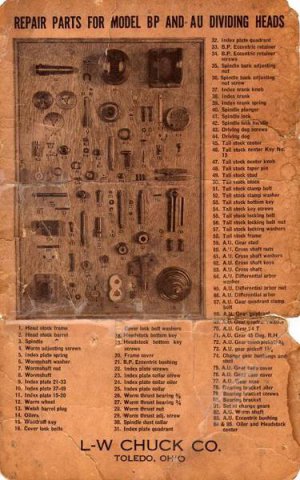

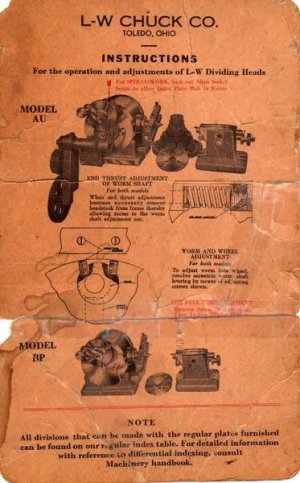

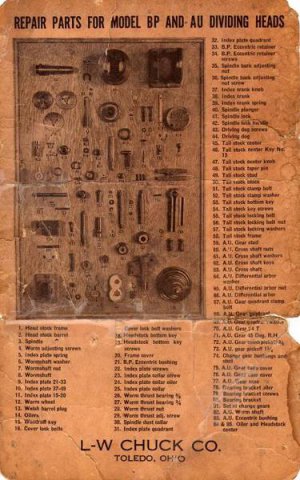

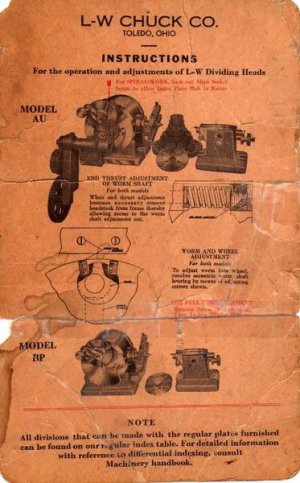

Ok, so I built up a little courage and started taking it apart. I am at the point where I am ready to take out the spindle and then the worm screw. I can't tell from your photos for sure, but my assumption is that on the back side of the main spindle, I back out a set screw, then turn the keeper ring? and it should come out, right? Is it left hand or right thread? And same questions for the worm screw?

Also, I notice that there is some rust, like maybe a little water got inside. What would you recommend to remove it with? Would I be better dipping all the parts in diluted muriatic acid?

Regards,

John

Also, I notice that there is some rust, like maybe a little water got inside. What would you recommend to remove it with? Would I be better dipping all the parts in diluted muriatic acid?

Regards,

John