Question. The orange motor drive belt is shredding away at the edges. I think it may be too large for the motor pulley; but not sure. It is an interesting set up in that the belt is a "V" belt and the counterbalance pulley is flat while the motor pulley is a V. Should I just use the belt as is so I can try some turning, or should I get a new V belt. Other options and comments welcome. Here are some photos.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Just Acquired a SB 9A. Questions.

- Thread starter ShagDog

- Start date

- Joined

- Sep 28, 2013

- Messages

- 4,318

I'd get a new belt, they're not expensive. Gates AX (1/2" wide) V-belts are really nice and wrap well around small pulleys.

- Joined

- Oct 16, 2019

- Messages

- 6,591

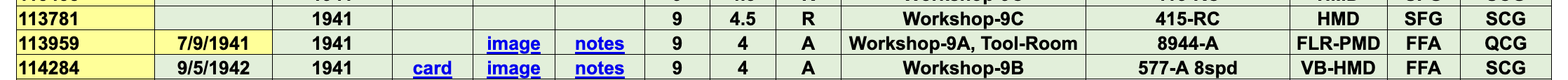

Can you post a picture of the serial number?Another question. The serial # is 113591 JFP. Could not find anything in my search with the letters JFP. Anyone know what the approximate date might be?

- Joined

- Nov 29, 2017

- Messages

- 533

I think you can call SB and they can help you with this....used to be able to anyway.Another question. The serial # is 113591 JFP. Could not find anything in my search with the letters JFP. Anyone know what the approximate date might be?

- Joined

- Oct 14, 2013

- Messages

- 997

That looks just like -my- first lathe! It's a great machine!

You need to plan to make one of these for when the "oh, #$%! My chuck is stuck!" Moment arrives... a 3D printed one would almost certainly work. Mine was hand filed and semi-broached off my spare/broken back gear.

I'm also voting for "swap the spindle felts". I wish I had done it earlier! Pulling the spindle isn't all that difficult. The hard part is finding the courage to do it! You can pump oil into those felt holding holes if you want to flush things a bit. It won't clear the sump, though. 100% chance your felts are hard and crudded up if they haven't ever been changed (like mine)...

And clean, clean, clean the spindle threads (inside and outside)!

Sent from my SM-G892A using Tapatalk

You need to plan to make one of these for when the "oh, #$%! My chuck is stuck!" Moment arrives... a 3D printed one would almost certainly work. Mine was hand filed and semi-broached off my spare/broken back gear.

I'm also voting for "swap the spindle felts". I wish I had done it earlier! Pulling the spindle isn't all that difficult. The hard part is finding the courage to do it! You can pump oil into those felt holding holes if you want to flush things a bit. It won't clear the sump, though. 100% chance your felts are hard and crudded up if they haven't ever been changed (like mine)...

And clean, clean, clean the spindle threads (inside and outside)!

Sent from my SM-G892A using Tapatalk

- Joined

- Oct 16, 2019

- Messages

- 6,591

If you go to www.wswells.com you can look at the serial number database and narrow down the year of manufacture.

- Joined

- Oct 16, 2019

- Messages

- 6,591

That's an interesting idea. Do you have a picture of where that mounts?That looks just like -my- first lathe! It's a great machine!

You need to plan to make one of these for when the "oh, #$%! My chuck is stuck!" Moment arrives... a 3D printed one would almost certainly work. Mine was hand filed and semi-broached off my spare/broken back gear.

I'm also voting for "swap the spindle felts". I wish I had done it earlier! Pulling the spindle isn't all that difficult. The hard part is finding the courage to do it! You can pump oil into those felt holding holes if you want to flush things a bit. It won't clear the sump, though. 100% chance your felts are hard and crudded up if they haven't ever been changed (like mine)...

And clean, clean, clean the spindle threads (inside and outside)!

Sent from my SM-G892A using Tapatalk