-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Joined the Lagun club today.

- Thread starter akjeff

- Start date

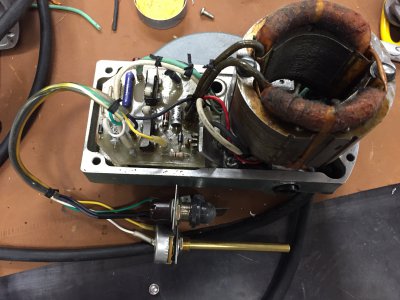

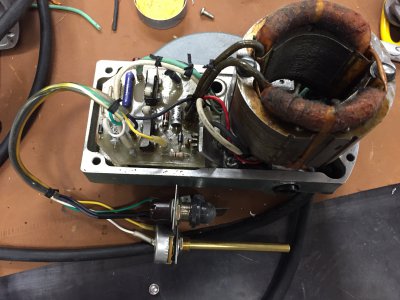

Dove into the power feed today. Found out this Lagun branded unit is not a re-badged Servo 100, instead it's a re-badged Servo 70 type. Big shout out to Wayne at https://www.icai-online.com. Huge help, and new speed control potentiometer and brushes are on the way. Also going to replace the two electrolytic caps on the board as a precautionary measure, along with the deteriorated 40+ year old wiring. Bearings all feel smooth. Motor looks good after a little cleanup. It ran just fine, it just had no speed adjust. Hopefully, I'll be able to get it back together, and working. If I had any common sense, I'd replace it. But, it was OEM on the machine, and I'd like to keep it that way.

- Joined

- Apr 23, 2018

- Messages

- 6,532

No reason to replace what can be rebuilt with available parts.

My Lagun/Servo "100" needs a new rapid switch. I'm going to give that shop a try. Thanks for the link.

My Lagun/Servo "100" needs a new rapid switch. I'm going to give that shop a try. Thanks for the link.

I know the use of swivel bases are frowned upon by many( including myself for a time ) due to added error, and a reduction in rigidity, but I do like the convenience of either turning it 90 degrees when needed, or for making angled cuts/bevels. Rigidity won't be an issue for me, as I have no need to take heavy cuts or otherwise beat on the machine. The additional error( if any ) would bother me. So, mounted the swivel base( using a pair of sine keys ), bolted the vise back in place, and indicated in the fixed jaw. Then I swept the indicator across both of the bed ways of the vice in both X and Y directions and got next to nothing more than a heavy needle wiggle. Should be just fine for my purposes. Also, hats off to both Kurt and Lagun for precision. After indicating in the back jaw, the graduations on the vise/swivel base read dead on zero. You'd need a magnifying glass to get it any closer!

Those jaws are extremely handy! I had them on my 4" and loved them. When I got this used vise, it was just dumb luck that it had the very same jaws. Sure nice not having to fool with parallels near as often.If I haven't said so, your step jays are awesome.

a thing to remember about the swivel base is that it comes off or goes on at your pleasure. Nice option!

Brief update. The new speed control potentiometer and other parts arrived for the power feed. Installed the pot, new wiring, brushes, and electrolytic caps. Power feed now back up and running.....almost. While re-wiring and assembling the limit switch, the brittle 40+ year old plastic housing of the micro switches shattered like glass. Replacements on the way, and hopefully that will be it.

The long term parts support, is sure nice. Virtually every electronic component is off the shelf. The only oddball, is the SCR in the foreground of the photo. They were made to spec, and still available! The knob that goes on the shaft of the speed control pot, are still in use on present day drives, with the same part number! And yes, an old school AC motor. No logic controls here. Line voltage flows through the limit switches( they're normally closed ) and kill power to unit when you hit a stop. Crude, but effective! The only part I needed, that was no longer available, was the gasket between the top and bottom halves, so I made one out of fiber paper. I won't be using flood coolant, so chip/dirt protection is all it'll need.It's nice that you can get all the parts. Electrically, the unit looks like a lot of off the shelf parts which is awesome. That's an AC motor?

Edit to add that the micro switches and variable knob arrived. Power feed is now functioning as designed.

Last edited: