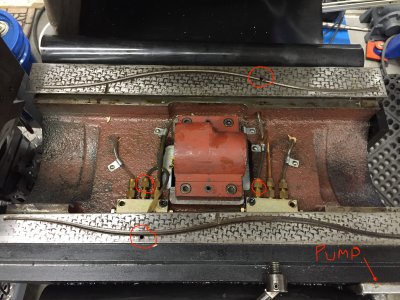

Slowly but surely getting this machine 100% operational. Was seeing very little oil getting to the ways of the X-axis, the backside in particular. So after the turkey hangover wore off this morning, I went out to the shop to get to the bottom of it. Was surprised at how easy it was to remove the table. 15 minute job. Wheeled my welding table next to the mill, and adjusted the knee until they matched up, and slid it off. Found that the metering valves that feed the X-axis ways, along with the tubing, were plugged up; the rear one more so than the front. Will just replace all the meters and tubes. This stuff is 40+ years old, and no use in half assing it. Pump works great, and the manifolds are fine. Also, part of the process of removing the table is removing the left side crank/end cap to remove the lead screw. When I pulled it, found that the bearings felt rough/notchy. Pulled the Y-axis as well, and found the same. Again, 40+ years old, just replace the damn things. Found two packs of Timken 6204 ZZ's for $21/pair. They're on the way. Will contact Carmen at Lagun on Monday, for the metering valves, as we've already talked about what I was likely to find, and he has them in stock. Both lead screws and the nuts look great. Was also pleased at how much flaking was still visible on the ways. For being made in 1978, I think they look damn good!