- Joined

- Apr 21, 2015

- Messages

- 582

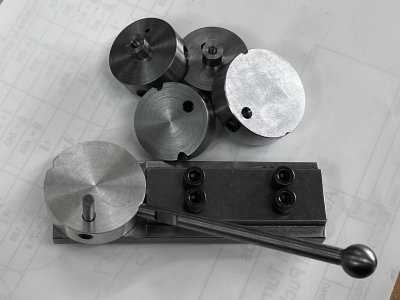

Just a note that I just published the third and final part of the ball turner build notes.

(I’ve gotta stop typing markdown for these posts!)

I'm really glad I built mine. I expect I'll be putting ball handles on darn near everything going forward.

(I’ve gotta stop typing markdown for these posts!)

I'm really glad I built mine. I expect I'll be putting ball handles on darn near everything going forward.

Last edited: