- Joined

- Apr 8, 2013

- Messages

- 1,982

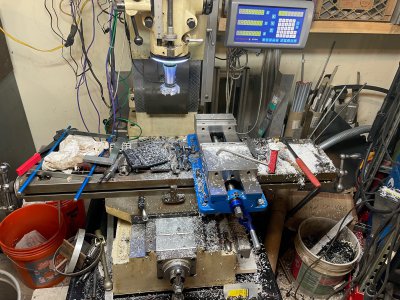

I got the the mid stage of a milling job and looked at my tooling all covered with chips. Wanting to be neat like the guys on this site I decided to blow my tools off at 40psi and vacuum the area. As soon as the air hit the first tool there was a rifle shot and a mushroom cloud from my VFD. Upon disassembly I found three places where heavy wiring had vaporized leaving 3/4 inch diameter black circles. One of these was a lead on an IC. TOAST! Ordered another VFD. I was about 2 feet below the unit yet the chip had gone in thru a cooling grate on the top. Yup, it sucks 2B me!