- Joined

- Dec 18, 2019

- Messages

- 6,464

POTD- PROJECT OF THE DAY: What Did You Make In Your Shop Today?

Post #'s: 3,324 - 3,326 on Page 111.

There's probably an easier way to attach the link, but I don't know how to do it.

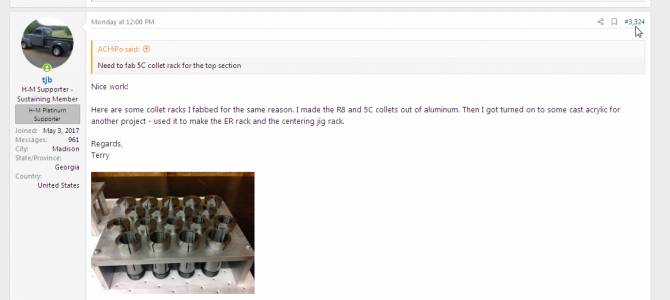

Indeed. Just starting my machining journey, so really didn't have much tooling to choose from. Thanks for the link. Basically, I'm trying to fit my toolbox drawer as well. Hope mine come out as well as yours did!There are all kinds of ways to do this. If you have none of the necessary tools to do the job and you had to buy something, I think I would go with annular cutters. But if you have something that works, it may make sense to use it. Here's a link to how I made mine:

POTD- PROJECT OF THE DAY: What Did You Make In Your Shop Today?

Post #'s: 3,324 - 3,326 on Page 111.

There's probably an easier way to attach the link, but I don't know how to do it.

Regards,

Terry

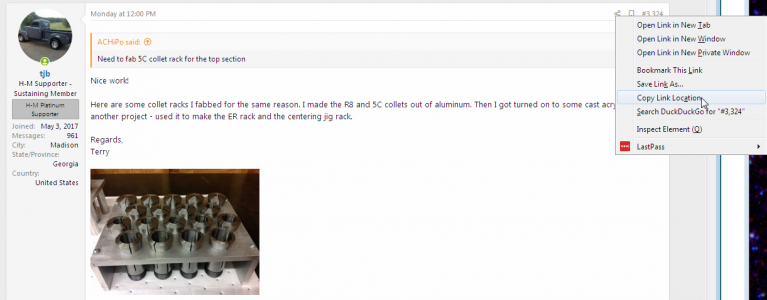

Thanks, Brino.Here's how I do it (old version of firefox on win7) :

find the post you want to link to and hover the mouse cursor over the post number and right-click, and choose "copy link location"

Here it is in pictures (screen captures):

View attachment 335962

View attachment 335963

Then use the little chain icon (insert link button) to paste in the url.

View attachment 335964

Here's the direct link for post #3324:

https://www.hobby-machinist.com/thr...you-make-in-your-shop-today.67833/post-772678

and for post #3326:

https://www.hobby-machinist.com/thr...you-make-in-your-shop-today.67833/post-772737

-brino

EDIT: By the way, Great job on those Terry!

Good choice, in my opinion.Indeed. Just starting my machining journey, so really didn't have much tooling to choose from. Thanks for the link. Basically, I'm trying to fit my toolbox drawer as well. Hope mine come out as well as yours did!

I looked through what I had to see if there was something that would work and not kill me. Don't have a boring head yet. The step drill that I did have was junk. The biggest drill I have is 1/2". The Sherline flycutter I have is slightly too large in diameter, and really isn't made for boring. So I ended up with getting the annular cutter. Hope to have it late next week. Probably will buy a better step drill as well, as they seem like they could be handy for some things.

Thanks, Brino.

Learn something new everyday.

Regards,

Terry