- Joined

- Aug 1, 2022

- Messages

- 137

The spindle is done.

I turned a 1/4” thick washer to an ID of 36mm and an OD of 61mm to help press in the angular contact bearings. Using this, both inner/outer races are pressed at the same time while the slightly smaller OD and larger ID ensures that this washer falls out easily after installation.

With new bearings, the quill was reassembled and a healthy dose of Mobilegrease 28 added in the quill via the two grease screws.

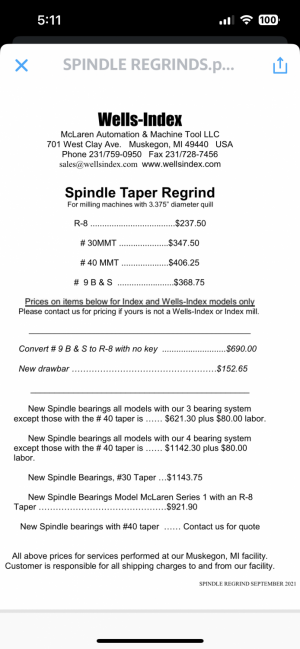

Did some light woodworking to support the quill/spindle for shipping. It’s going back to Index-Wells for an R8 conversion and new drawbar.

Pics:

I turned a 1/4” thick washer to an ID of 36mm and an OD of 61mm to help press in the angular contact bearings. Using this, both inner/outer races are pressed at the same time while the slightly smaller OD and larger ID ensures that this washer falls out easily after installation.

With new bearings, the quill was reassembled and a healthy dose of Mobilegrease 28 added in the quill via the two grease screws.

Did some light woodworking to support the quill/spindle for shipping. It’s going back to Index-Wells for an R8 conversion and new drawbar.

Pics:

Last edited: