-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I’d like to blame the tool, but…

- Thread starter AlfromNH

- Start date

- Joined

- Dec 18, 2019

- Messages

- 6,464

Looking a little bit better, but still ragged. You might want to reduce your stick out a bit. 4:1 is ok, 8:1 is not so good. Less is better. The stick out ratio is the ratio of the length protruding from the chuck to the diameter. At longer stick outs you are getting deflection of the work piece and probably are chattering. It's a challenge for people starting out, since they tend to want to have larger stick outs than they should, perhaps since they are a little intimidated getting the bit too close to the chuck (and disaster). What is your threading RPM? Is the cutter tip centered on the spindle height? Do you know how to set it to the correct height? What is your technique? There are lots of ways to do it, just wondering what yours is.Adjusted the compound angle and used WD-40. Not great, but much better

First pass:

View attachment 440556

Not sure how deep to go. This is 24 TPI

View attachment 440557

All that being said, sometimes it is the material. Sometimes you get stuff that doesn't machine very well, whatever you do. It's something that can happen when you buy/acquire materials that you don't quite know what is in it. (Alloy type, etc.)

For thread depth, you can use trig, but in the end, you need to be able to measure that your threads are good. The cheapest thing to do is to use a nut - but you have no guarantee the nut really is to spec. This is usually not an issue if you are doing everything in house. But if you are to match up to someone else's hardware, you should measure the thread pitch diameter. The most common and old school method is to use thread wires and a micrometer. This uses 3 wires, two on one side and one on the other, and some formulas. The thread wires are pretty inexpensive. There's also a 1 wire method which is ok, but subject to some error. And finally, there are thread micrometers. For the pitch diameters, you can use an app, or look it up online, or get yourself a copy of Machinery's Handbook. And older edition is just fine. I am using a copy from 1962... I strongly recommend a copy of Machinery's Handbook - there's a ton of good stuff in there.

- Joined

- Nov 1, 2022

- Messages

- 140

Thanks for sticking with me. I've reduced the tool stick out.

To set the tool height I put a center drill in the tailstock Chuck, swivel the compound and eyeball tool to drill.

I've been running the spindle at 500rpm.

The aluminum is stock i got from the deceased po's collection I got with the machines. I don't know the alloy.

To set the tool height I put a center drill in the tailstock Chuck, swivel the compound and eyeball tool to drill.

I've been running the spindle at 500rpm.

The aluminum is stock i got from the deceased po's collection I got with the machines. I don't know the alloy.

- Joined

- Dec 18, 2019

- Messages

- 6,464

No problem. I didn't start this machining journey that long ago - I think I still remember a lot of my mistakes!Thanks for sticking with me. I've reduced the tool stick out.

To set the tool height I put a center drill in the tailstock Chuck, swivel the compound and eyeball tool to drill.

I've been running the spindle at 500rpm.

The aluminum is stock i got from the deceased po's collection I got with the machines. I don't know the alloy.

If you have a small steel scale, like a 6" one, you can use it to center your cutter. It's kind of a neat trick. What you do is slowly bring your cutter up to the stock (smooth) and lightly sandwich the scale between the stock and the cutter tip. If you are very close to center, the scale will be vertical. If the top of the scale is tilting towards you, then the tip is too low, and tilting away, means the cutter is too high. Try this and see how the tip is set, and adjust accordingly. I think it is more accurate than eyeballing, at least for me. Try it out.

Hope that helps. What are you using for a cutter? Can you take a close up picture of it and post it?

That is a neat trick, I have a 6” scale and will try it out. Does 500rpm sound reasonable?

Judging by the looks it seems the stock is 15~20mm thick (3/4in?) 500rpm is an OK speed for threading this size aluminium with hss. It would be pretty slow for normal turning being only about 25m/min (75sfpm), but threading is usually done slower anyway.

If you find the piece deflects and you're getting a thread that's loose as you're screwing a test nut further towards the chuck there are two ways to resolve it. One, cut a centre on the end and support the workpiece with the tailstock. Two, nearing target depth make spring passes after finish passes (same direction, same depth of cut as previous one).

South Bend, and, I suspect, most American lathe builders set their degree readings so 0* was perpendicular to the bed. It seems the Asian builders set 0* to be parallel with the bed. My rule of thumb is to set the compound so it feeds parallel with the trailing flank of the tool, then move it 1/2* toward perpendicular to the bed.

Unless you are using a carbide full thread insert that cuts the full profile of the thread, the threading tool will likely raise a burr on the crest of the thread. On external threads the burr can best be removed with a file. I use a mill file or long angle lathe file.

European lathes I saw are like Asian ones in this. 0 degrees is parallel to the bed.

For deburring internal threads I used sandpaper on a piece of soft wood... It is sort of OK.

Personally every solid aluminium round I ever got was 7xxx series. It is very strong, it machines very well, but it is considered unweldable. Tubing is often 6xxx and cheapest plate/sheet is often 2xxx/1xxx here in EU.

I like alcohol(denatured, or isopropanol) as cutting fluid for aluminium. Also WD40 will do too.

- Joined

- Dec 18, 2019

- Messages

- 6,464

There's a lot of 6061 round stock here. 6061 is weldable and machines ok. I have machined 7075 on the mill, and it machines great. But I haven't seen much 7xxx round stock available.Judging by the looks it seems the stock is 15~20mm thick (3/4in?) 500rpm is an OK speed for threading this size aluminium with hss. It would be pretty slow for normal turning being only about 25m/min (75sfpm), but threading is usually done slower anyway.

If you find the piece deflects and you're getting a thread that's loose as you're screwing a test nut further towards the chuck there are two ways to resolve it. One, cut a centre on the end and support the workpiece with the tailstock. Two, nearing target depth make spring passes after finish passes (same direction, same depth of cut as previous one).

European lathes I saw are like Asian ones in this. 0 degrees is parallel to the bed.

For deburring internal threads I used sandpaper on a piece of soft wood... It is sort of OK.

Personally every solid aluminium round I ever got was 7xxx series. It is very strong, it machines very well, but it is considered unweldable. Tubing is often 6xxx and cheapest plate/sheet is often 2xxx/1xxx here in EU.

I like alcohol(denatured, or isopropanol) as cutting fluid for aluminium. Also WD40 will do too.

WD40 is fine for cutting fluid, haven't tried iso-propanol, not sure I want to, due to its flammability and high vapor pressure. I don't have terrific ventilation in my shop, don't want to fill the area with vapors.

- Joined

- Jan 2, 2014

- Messages

- 8,854

two things:

1) When @WobblyHand said this:

He was referring to the unsupported stick-out of the work from the chuck.

If too long for the diameter the work will actually push away from the tool, especially it it's not sharp enough.

The answer is to support the right end with a live centre in the tailstock.

I like a long small diameter one to not interfere with the tool post.

You replied with:

That helps too, but from your photos it was already not bad.

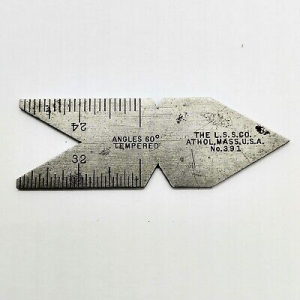

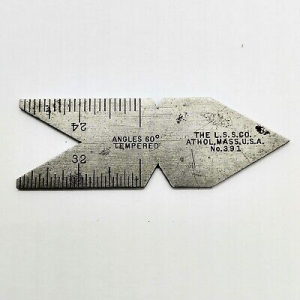

2) Are you sure your tool is 60 degrees included angle?

it looks kinda pointy to me.

Did you check it against a "fish-tail" gauge?

Of course it might just be the angle of the photos..... hard to tell from here.

Okay one more thing I like low-odor lamp oil from the hardware store for cutting aluminum.

Keep making progress, we will get you there!

Brian

1) When @WobblyHand said this:

You might want to reduce your stick out a bit. 4:1 is ok, 8:1 is not so good. Less is better. The stick out ratio is the ratio of the length protruding from the chuck to the diameter.

He was referring to the unsupported stick-out of the work from the chuck.

If too long for the diameter the work will actually push away from the tool, especially it it's not sharp enough.

The answer is to support the right end with a live centre in the tailstock.

I like a long small diameter one to not interfere with the tool post.

You replied with:

I've reduced the tool stick out.

That helps too, but from your photos it was already not bad.

2) Are you sure your tool is 60 degrees included angle?

it looks kinda pointy to me.

Did you check it against a "fish-tail" gauge?

Of course it might just be the angle of the photos..... hard to tell from here.

Okay one more thing I like low-odor lamp oil from the hardware store for cutting aluminum.

Keep making progress, we will get you there!

Brian

WD40 is fine for cutting fluid, haven't tried iso-propanol, not sure I want to, due to its flammability and high vapor pressure. I don't have terrific ventilation in my shop, don't want to fill the area with vapors.

Yes, it is flammable and evaporates very fast. I definitely would not use it as a flood coolant... I have a spray bottle filled with it and when machining aluminium I give it a spray from time to time. I choose it over WD40 mostly due to its low price and clean evaporation.

I have to try that. I tried kerosene before, it worked nicely for tapping, but I hated the smell.Okay one more thing I like low-odor lamp oil from the hardware store for cutting aluminum.

Keep making progress, we will get you there!

Brian