- Joined

- Apr 23, 2018

- Messages

- 6,532

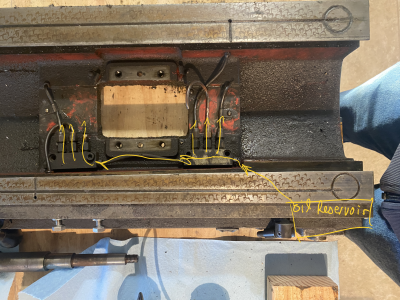

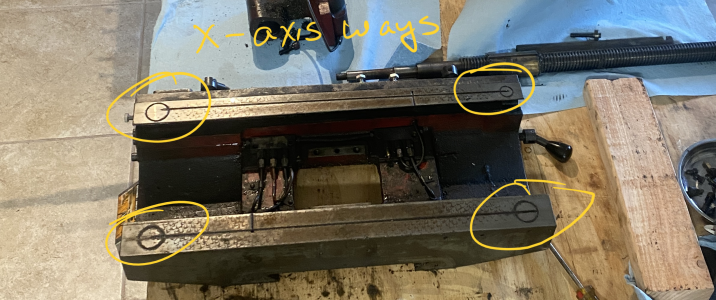

Thanks. I’m trying to make sense of the lubrication system - hope to have a manual soon.

Jim, I don't think the manual covers the plumbed lubrication systems. I think they were add-ons that were fit to order when the machines landed in L.A., same as power drawbars and servo drives. I'd have to look to be 100% certain, but I don't recall seeing any of it in the diagrams or parts lists.