- Joined

- Apr 24, 2021

- Messages

- 463

I did it at zero this time.Your compound angle is off. Asian lathes don't have consistent markings. If your index says 29.5, try setting it to 61.5 and try again.

I did it at zero this time.Your compound angle is off. Asian lathes don't have consistent markings. If your index says 29.5, try setting it to 61.5 and try again.

I’ll try that next. I chased it with a die and it helped, but I don’t have the money for a whole die set to chase every thread I try to cut.I did it at zero this time.

Your part looks good. Nice job!500 RPM is what I use. Turning the tool upside down, running the spindle in reverse thus feeding away from the chuck will save your nerves when threading at higher RPMs. Also turning a relief near the shoulder will be very helpful.

What makes you say that Mikey? Cause of a previous post? Or because you can tell by looking at the threads that I wasn’t setup properly?I did it at zero this time.

What makes you say that Mikey? Cause of a previous post? Or because you can tell by looking at the threads that I wasn’t setup properly?

www.hobby-machinist.com

www.hobby-machinist.com

I do have and used a tailstock die holder. I also turned the diameter down to less than the 75% size (i think i went to 0.295”). And while it cut clean, i had to turn the chuck by hand (scared to try power feed…) and break the chip every 1/4 turn where it would say “snap!”. I was attempting to make turn buckles and have left hand tap and die for 5/16”. My lathe is setup for metric threads. The project sounded easy. It felt hard so i did what i do and quitYa it took a long time. I used a hss 3/8 blank. Now I know if I invest in fact tooling it will only get better. I calculate the sfm and came up with about 500 rpm. Can anyone confirm that’s correct?

on your project, do you have a tailstock die holder? I hear that’s a guaranteed way to do it.

I have struggled with this on my lathe since the beginning. Added a bronze thrust washer to the leadscrew to take up end play and it made a significant difference.Great start.You are almost there.

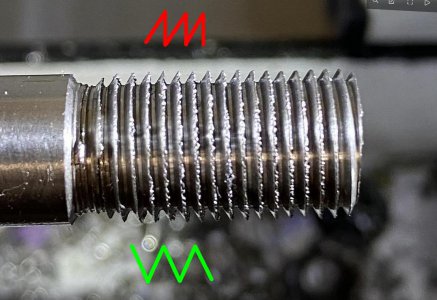

It kind of looks like your thread is not formed correctly and maybe are cutting too much on the back side.. The top of the threads seem to be folded over away from the chuck. The bottom of the threads look to be well formed. It's hard to tell but the front and back side angle does not look symmetrical. Also looks like it is cut too deep. What might help you is to take a few passes with a file before you take the final couple of threading passes, that should eliminate the folded over sharp tops and give you a more visually pleasing thread form. It almost looks like your cutting edge is not exactly perpendicular to the work.

A 28 degree approach is maybe a little much, 29 or 30 degrees might be better. With a properly ground 60 degree tool, you can plunge straight in with the approach perpendicular to the work, but this does not always work well. If you swing your compound around to parallel to the work and step over 1 or 2 thou on each pass then feed in with the cross slide it works well also. A spring pass is a final pass without going deeper on the compound. It just cleans up the fuzz on the threads.

On a 1/2-20 thread, I turn the major diameter to 0.495 and thread to the proper minor diameter. This gives a better thread form with a bit of a flat on the thread peaks.

Here is an example of a 1/2-20 thread in 303 SS I did a few days ago. I'm not sure exactly where the ''chatter'' marks are coming from, but it may actually be chatter that I can't hear. Or it could be just the way the chip forms on 303 SS. 304 SS seems to be smoother on the thread faces, but we switched to 303 to save on tooling costs.

View attachment 365959