- Joined

- Jun 12, 2014

- Messages

- 5,065

I would suggest you give the Carmex lay down inserts with a 5/8" right hand external thread holder a try if threading toward the chuck. I would not cheap out on the inserts, the Carmex are about $16 each, I would get two, I am still using my first insert for 2+ years. You might also look into David's book "Introduction to Indexable Tooling for the Metal Lathe", lots of good points and specific recommendations for the holders and inserts.

www.hobby-machinist.com

www.hobby-machinist.com

Very simple to setup, and you get very clean cutting. David and I do quite a bit of threading in a wide range of materials and the laydown threading inserts have given very good results. You first need to make sure your cutting tip is at the right height and parallel to the chuck. To get it parallel to the chuck, I use a 123 chuck against the chuck face and bring the tool holder up against the other side of the 123 block and then tighten down your tool post nut. I use the compound locked, doesn't matter what the angle is, I feed each pass with the cross slide. I would at first cut a wider relief groove until you get more proficient and try increasing your threading RPM if using carbide inserts (I would start with 100-120 RPM depending on your gearing). Dimension your rod to the OD of the major thread diameter.

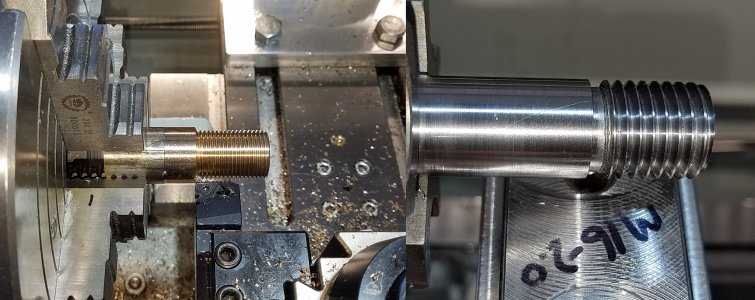

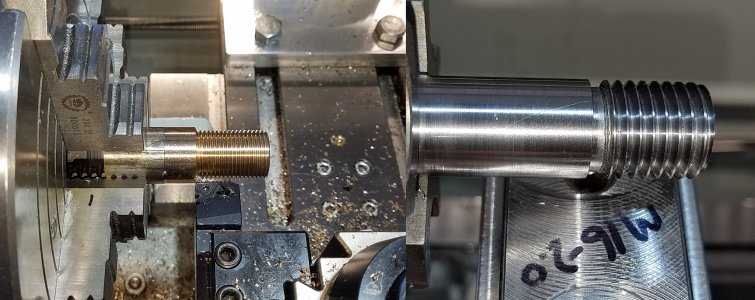

When you start threading, zero your cross slide dial at "0" when the tip of the cutter touches the OD of the rod. I typically take a series of continuous passes at sequential 0.01" depths until I am close to my target depth, then 0.005" and 0.002" and check the nut fit. You will almost always find the minor diameter will need to be a few thousandths deeper than what the dial indicates (i.e. the expected minor diameter). It also depends on the amount of flex in your work, on threading smaller rod I use a live center. You may need to use a fine file to take off the tips of the threads. A spring pass is done as a final pass, usually at the same diameter or 0.001" which should give you a very clean thread. Do not repeat spring passes as it will cause chatter and work harden some materials. You should be able to end up with threads similar to below.

Primer on Indexible Tooling for Lathes

I'm about 3 days into the cleanup of a new to me lathe. Running a mill for almost a year and I find lathe tooling bewildering. And the prospect of grinding my own tools is something I maybe should learn...but the odds of that happening are about -27%. I've asked around and searched this and...

www.hobby-machinist.com

www.hobby-machinist.com

Very simple to setup, and you get very clean cutting. David and I do quite a bit of threading in a wide range of materials and the laydown threading inserts have given very good results. You first need to make sure your cutting tip is at the right height and parallel to the chuck. To get it parallel to the chuck, I use a 123 chuck against the chuck face and bring the tool holder up against the other side of the 123 block and then tighten down your tool post nut. I use the compound locked, doesn't matter what the angle is, I feed each pass with the cross slide. I would at first cut a wider relief groove until you get more proficient and try increasing your threading RPM if using carbide inserts (I would start with 100-120 RPM depending on your gearing). Dimension your rod to the OD of the major thread diameter.

When you start threading, zero your cross slide dial at "0" when the tip of the cutter touches the OD of the rod. I typically take a series of continuous passes at sequential 0.01" depths until I am close to my target depth, then 0.005" and 0.002" and check the nut fit. You will almost always find the minor diameter will need to be a few thousandths deeper than what the dial indicates (i.e. the expected minor diameter). It also depends on the amount of flex in your work, on threading smaller rod I use a live center. You may need to use a fine file to take off the tips of the threads. A spring pass is done as a final pass, usually at the same diameter or 0.001" which should give you a very clean thread. Do not repeat spring passes as it will cause chatter and work harden some materials. You should be able to end up with threads similar to below.